Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

The Demag wheel blocking system has the characteristics of strong bearing capacity, high temperature resistance, wear resistance, precise positioning, long service life, and convenient maintenance in the electroslag furnace. The following is a detailed introduction to the necessity and characteristics of the travel wheel block in the electroslag furnace.

The necessity of the Demag modular drive system in an electroslag furnace

As heavy smelting equipment, such as steel, the furnace body and furnace cover of the electroslag furnace are usually very heavy. During operation, to complete tasks such as charging, slag removal, and maintenance, it is necessary to frequently lift the furnace cover or move the entire furnace body. Therefore, the electroslag furnace must be equipped with a reliable traveling wheel block to achieve these movements. The travel wheel block needs to operate in a high-temperature and harsh environment, withstand heavy loads, and maintain stability and precision to ensure the safety and precise positioning of the furnace body during movement. It can be said that only a travel wheel block system with high load capacity and high reliability can meet the needs of electroslag furnace operation.

Characteristics of the Demag wheel blocking system

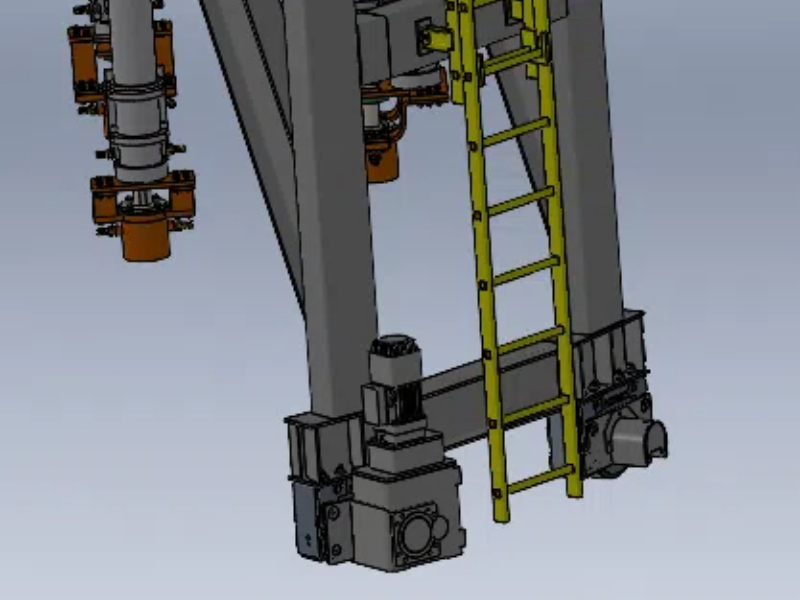

Strong bearing capacity: The bearing capacity of each wheel can reach tens of tons, which can easily support the weight of the electroslag furnace body at high temperature.

Smooth operation: Ductile iron wheels are used, which have self-lubricating properties and greatly reduce operating friction. Under precise control, the furnace body is ensured to be smooth, stable and accurately positioned during movement.

High temperature and wear resistance: Some models of wheel blocks have a high temperature resistance design and can adapt to external conditions above 150°C or bearing temperatures up to 350°C; ductile iron wheel hubs ensure excellent wear resistance.

Easy maintenance: The wheel block adopts a five-sided sealed casting shell to reliably protect the wheel set from mechanical impact; large bearings are lubricated for life and equipped with wear indicators, which can be remotely monitored, reduce daily maintenance workload, and extend the service life of the equipment.

DEMAG wheel blocks use proven and reliable components to provide extremely high functional reliability and easy maintenance. In industrial furnace car applications, Demag drive system can achieve precise positioning and effectively meet the requirements of high-temperature furnace cars for movement accuracy and safety. With these professional wheel block solutions, Shiyang provides reliable equipment guarantees for industries such as steel smelting.

DRS Double flange motorised wheel block system is also called the Demag wheel block system, which is quiet and smooth, fast stopping and starting, and energy-saving performance when moving heavy-loaded doors.

Demag wheel block system is a important component of modern industrial cranes and material handling systems, designed to provide superior performance in demanding environments.

Demag DRS wheel range provide durable, corrosion-resistant, and low-maintenance travel solutions for gantry cranes, ensuring reliable heavy-load handling in harsh environments.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.