Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

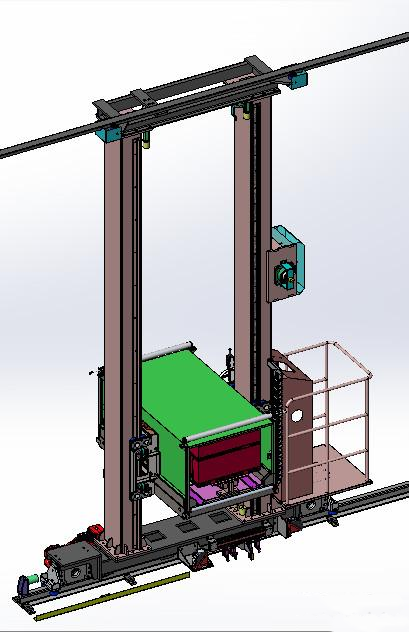

Demag rail wheels are widely used in single-column stackers, double-column stackers, rail-switching stackers, and other transfer equipment in automatic high-bay warehouses due to their flexible installation, high load-bearing capacity, low maintenance, multiple wheel types, installation methods, precise positioning, and customization.

In modern automatic high-bay warehouse systems, stackers, as core handling equipment, undertake high-density and high-frequency cargo storage and retrieval tasks. In order to achieve stable operation and precise positioning, the stacker operating mechanism places extremely high demands on the wheel system. Demag rail wheel blocks have become an ideal drive solution for the stacker industry with their modular structure, high load-bearing performance, and multiple installation methods.

Classification of Demag rail wheel blocks in stackers

Depending on the different structures and operating modes of stackers, Demag rail wheel blocks can be divided into the following configurations:

1. Driven wheel block (including reducer)

Used in the main operating mechanism of the stacker to achieve forward and backward movement along the track. A matching reducer, which can be customized according to speed and torque requirements.

2. Non-driven wheel block

Non-driven wheel: a solid wheel, not directly connected to the motor, plays the role of bearing, supporting, and balancing the equipment.

The core advantages of Demag track wheels

• Modular design, flexible installation

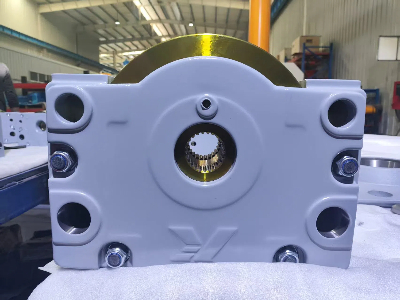

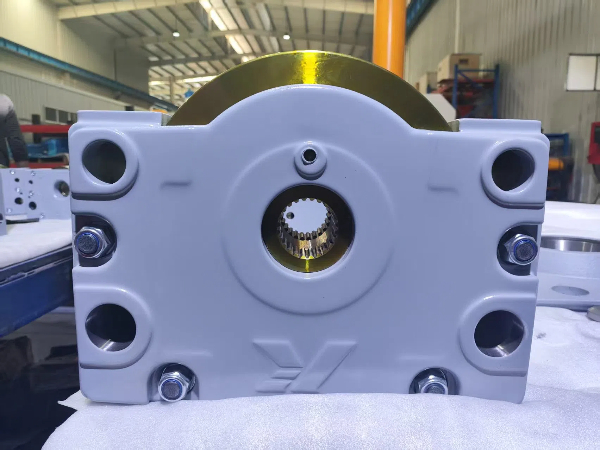

Demag wheel block adopts a ductile iron asymmetric box structure. Provides side installation, top installation, end installation, pin installation, and other methods to adapt to different stacker structure layouts.

• High load and low maintenance

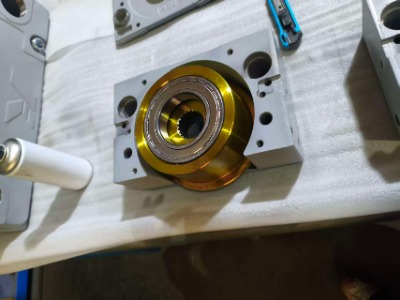

Equipped with GGG 70 spheroidal-graphite cast iron high-strength wheels and high-precision bearings, it has excellent wear resistance and long-term operation stability. Bearing pre-grease design reduces maintenance frequency and improves operation reliability.

• Smooth operation and precise positioning

The roundness and hardness of the wheels are strictly controlled, with low noise and low vibration during operation. Precise rail alignment capability can improve the alignment accuracy of stacker cargo and meet the needs of efficient warehousing.

• Customizable configuration

Provide a variety of wheel diameters(DRS 112-DRS 500), wheel widths, materials (such as cast iron wheels, polyurethane-coated wheels), and hardness options; Can be adapted to high-speed stacking systems or heavy-load cargo storage systems. The single wheel load of the walking wheel block is 2.75-40t, and other loads can be customized.

Applicable scenarios

Demag track wheel blocks are widely used in the following types of stacker systems:

Automatic stereoscopic warehouse stackers: used in high-density storage systems such as cold chain, medicine, food, and e-commerce.

Narrow channel single-column stackers: narrow operating paths, high requirements for track tracking accuracy;

Double-column stackers: with telescopic fork systems, heavy loads, and long operating distances;

High-speed shuttle stacking systems: high-frequency start and stop are required, and wheel blocks have strong fatigue resistance.

Pallet and material box storage stackers: different loads require a variety of wheel diameter configurations to match.

Demag wheel blocks provide stable, efficient, and low-maintenance operation guarantees for stackers with their highly modular design, high load capacity, and precise operation characteristics.

If you need a customized wheel block solution for your specific stacker equipment, please contact us for technical support and product samples.

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

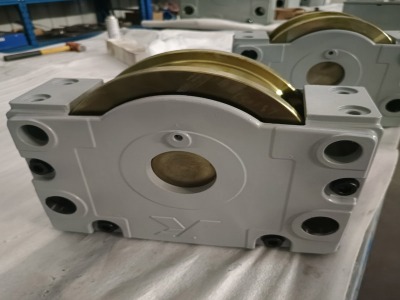

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.