With the acceleration of industrialization in Africa, the demand for efficient and safe lifting and transportation systems in industries such as port construction, mineral resource development, logistics warehousing and manufacturing has grown rapidly. As the world's leading provider of drive and travel technology solutions, the DRS wheel block system is being adopted by more and more African countries and is widely used in equipment such as bridge cranes, gantry cranes, and automated warehouse handling systems.

Industrial Modernization in Africa: Rising Demand for Advanced Travel Drive Systems

In recent years, countries such as South Africa, Nigeria, Egypt, and Kenya in Africa have increased their investment in infrastructure construction, mining, and manufacturing. In this development trend, local governments have put forward higher requirements for travel systems with high load-bearing capacity, strong durability, and easy maintenance.

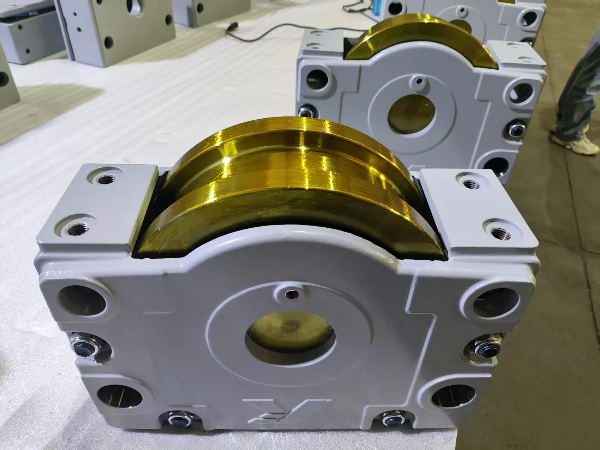

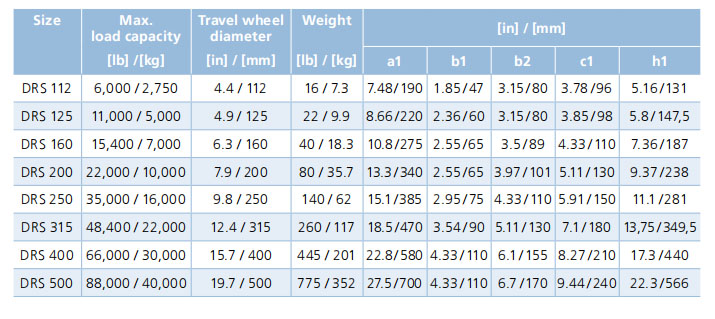

DRS Wheel Block Series Models

Demag DRS wheel block system covers a variety of specifications, suitable for different load and structural requirements. The following are the main models and their approximate load capacity range:

Customers can choose DRS wheel blocks of different models and configurations according to equipment load, travel speed, installation method and other requirements.

Main Features of the Demag DRS Wheel Block System

• Modular Design

Standardized structure, flexible selection, can be quickly integrated into various equipment, saving design and manufacturing costs.

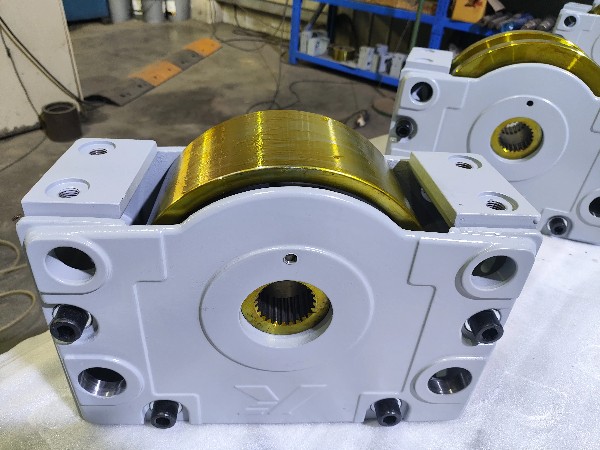

• Multiple Installation Methods

Preset top, side, end, pin and other installation interfaces to adapt to different structural forms, convenient installation and maintenance.

• High Load-bearing Performance, Compact Structure

High load-bearing capacity is achieved in a compact size, suitable for working conditions with limited space but heavy load.

• Maintenance-free Design

The wheel block adopts a closed structure, and the internal bearing is pre-filled with grease, which can achieve long-term maintenance-free operation and meet the needs of projects in remote areas of Africa.

• Compatible Drive System

Can be matched with Demag's own reduction motor system (such as offset drive) to build a complete travel drive solution.

• Available Wheel Material Options

Optional ductile cast iron wheels, polyurethane rubber-coated wheels, steel wheels, etc. can be selected to meet different ground conditions and usage requirements.

Typical Application Scenarios in the African Market

• Automated warehousing: Double flange DRS 112 has a load capacity of 2.75t and is suitable for the RGV/AGV trolley travel system in smart warehouses.

• Photovoltaic panel installation vehicle: DRS 125 wheel block with polyurethane rubber-coated wheels to prevent crushing of photovoltaic modules.

• Port logistics: DRS 160 is used as the support and drive wheel set of container yard gantry cranes and loading and unloading bridges.

• Mining industry: Single-flange DRS 250 is used as the driving and walking part of the lifting system in heavy metallurgical plants and open-pit mines.

• Hydropower station gantry crane: The lifelong self-lubricating design of the DRS 315 wheel block solves the problem of grease contamination of water bodies.

• Wind turbine hoisting system: Multiple sets of DRS 400 wheel blocks are connected in parallel to carry thousand-ton cranes on temporary tracks.

• Industrial manufacturing: DRS 500 has a load capacity of 40t and is suitable for crane systems and conveying equipment in steel mills and large machinery plants.

The export and application of Demag DRS wheel block systems are promoting the upgrading of equipment in multiple industries in Africa. With its outstanding performance, flexible modular design and global service capabilities, Chinese manufacturers are becoming a trusted partner for African industrial customers.

In the future, as the African market continues to invest in smart manufacturing and high-end equipment, Chinese manufacturer Shiyang will continue to provide customized, low-cost, high-quality travel system solutions.