Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

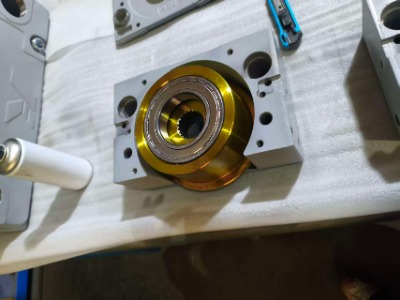

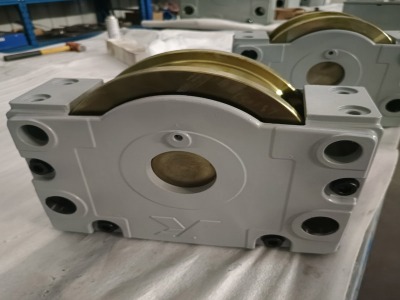

The Demag DRS 200 motorised wheel block system comprises heavy-duty, precision-engineered travel wheels designed for industrial rail transfer carts. Built to perform in demanding environments such as steel mills, foundries, and automotive manufacturing plants, these forged travel wheels deliver exceptional durability and smooth operation, minimizing downtime while maximizing productivity.

Key Features of the Demag DRS 200 Wheel Blocks

Heavy-Duty Load Capacity: Capable of supporting extreme loads up to 10 tons, the DRS 200 is ideally suited for transport of metals, heavy machinery, and bulk materials.

Precision Engineering: Manufactured from high-grade forged steel or ductile iron, each wheel undergoes strict quality inspections and repeated testing to ensure perfect alignment, reduced rail wear, and extended service life.

Heat and Shock Resistance: Specialized heat treatment and hardened surfaces provide reliable performance under thermal stress and mechanical shock, making these wheels especially suitable for steelmaking and foundry applications.

Low-Maintenance Design: Equipped with sealed bearings and corrosion-resistant coatings to withstand harsh operating conditions.

Specifications of the Transfer Cart Wheel Set

Material: Forged steel or ductile iron, with hardened tread and self-lubricating design for smooth operation.

Rated Load: 10 tons per wheel set. Overloading is not recommended.

Operating Temperature: Withstands temperatures up to 600°C (1112°F), suitable for high-temperature environments such as steel mills.

Compatibility: Available in single flange, double flange, flangeless (with guide wheels), and V-type configurations to suit various track layouts. Custom designs can be provided for special rail types.

Easy Installation: Housing is pre-designed with multiple connection points (top, side, pin, and end) to accommodate different mounting requirements, facilitating quick and convenient equipment replacement.

Applications of Heavy-Duty DRS Travel Wheels

The DRS 200 Demag wheel system is widely trusted across industries requiring robust and reliable transfer solutions:

Steel mills: Transport of raw materials, in-process goods, and finished products

Automotive plants: Movement of heavy presses and assembly line components

Ports and logistics: Handling of containers and bulk cargo

Contact our expert team now for free technical consultation and project proposals!

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.