Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

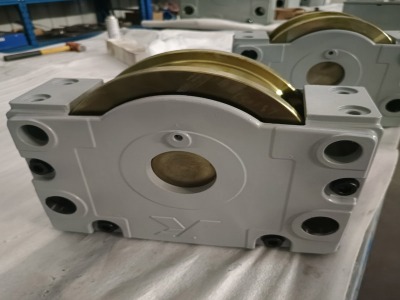

In heavy-duty logistics, automated warehousing, and crane travel mechanisms, the stability of the wheel block system directly dictates the reliability of the entire machine. This article provides an in-depth dissection of the DRS 315-NA-A-90-B-X-X wheel block to reveal the logic behind its design.

I. Decoding the Model Identification

Every character represents a physical attribute of this industrial unit. By breaking down the nomenclature, we can construct a complete profile of the product:

DRS 315: As a large-scale specification in the DRS series, "315" represents the structural volume of the wheel block, capable of supporting extremely high static and dynamic loads.

NA: Specifies that this unit is a "Non-Driven" (Idler) wheel. It does not connect directly to a motor; its primary functions are load-bearing and directional balance, typically used in tandem with an "MA" driven wheel.

A: Equipped with a dual-flange travel wheel made of high-performance spheroidal graphite cast iron (GGG 70). This design is a classic "rail follower," where the dual flanges effectively prevent crabbing or skewing.

B (Pin Connection): A highly flexible mounting method. The pin connection allows the wheel block to pivot slightly within the mounting seat, compensating for elastic deformation of the steel structure under heavy loads.

X-X (Basic Configuration): Indicates that this unit is not equipped with horizontal guide rollers or a gearbox interface. It is a minimalist, high-efficiency basic load-bearing unit.

II. Core Technical Advantages

1. Superior Material Engineering

The GGG 70 nodular cast iron used in this model offers exceptional wear resistance and self-lubricating properties. During long-term friction against the steel rail, it maintains an extremely low wear rate, significantly extending the maintenance intervals of the entire travel system.

2. Flexibility of Modular Design

Although this specific model (B-structure) utilizes a pin connection, the DRS series is inherently modular. This means if operational requirements change, you can easily find compatible drive solutions or alternative connection accessories based on the 315 size, reducing the complexity of spare parts management.

3. Precise Guiding Performance

The Type A dual-flange design is the preferred choice for indoor cranes and rail-mounted transfer cars. It eliminates the need for complex sensors or external physical guiding devices; the physical limit between the wheel flanges and the rail ensures path accuracy even across large spans.

III. Typical Application Scenarios

The DRS 315-NA-A-90-B-X-X is commonly found in the following equipment:

Heavy-duty Double-girder Cranes: Serving as support wheels for the long-travel mechanism to distribute the pressure of the main girder.

AS/RS Stacker Cranes: Providing stable load-bearing on the bottom travel rails of automated warehouses.

In-plant Material Transfer Carts: Acting as the non-driven wheel set to facilitate the movement of high-tonnage cargo alongside the driven end.

IV. Selection and Installation Recommendations

Compatibility Check: When installing this idler wheel, ensure that the travel speed and diameter of the driven end (MA) are perfectly synchronized to prevent "rail gnawing" caused by minute differences in wheel diameter.

Maintenance Focus: Due to the pin connection, it is recommended to regularly inspect the wear and lubrication status of the pins to ensure the wheel block can freely micro-adjust its position under load.

Conclusion

The DRS 315-NA-A-90-B-X-X is a heavy-duty idler unit characterized by balanced performance and structural purity. By stripping away complex attachments and returning to the essential functions of load-bearing and guiding, it stands as the ideal choice for rail travel systems seeking cost-effectiveness and long service life. 【Request for Quote】

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.