Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

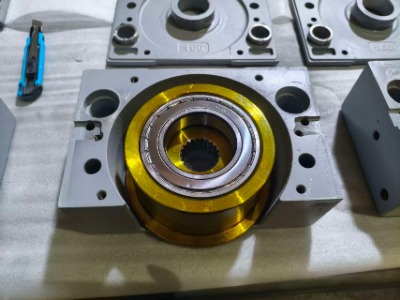

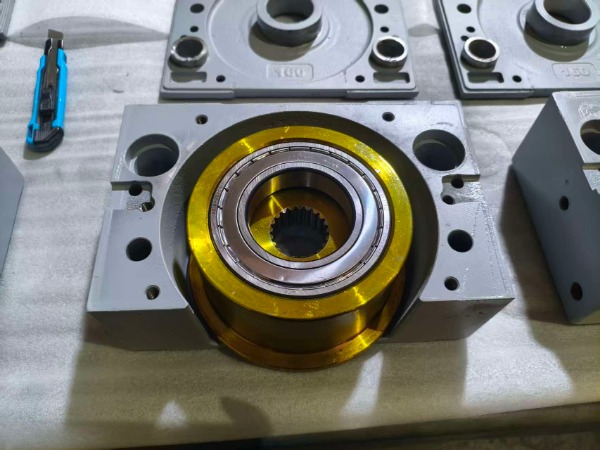

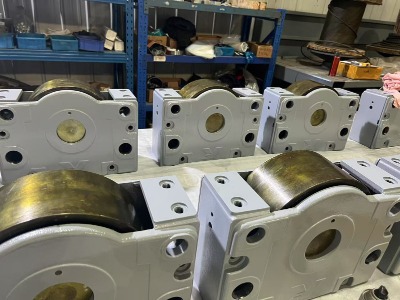

The Demag DRS Wheel Block System is a classic, high-quality travel component widely utilized in industrial cranes and material handling systems. The specific model number DRS-160-A45-B-0-18B-H-A30 encapsulates all the core technical specifications of the unit.

1. Model Code Breakdown

Code Segment | Meaning | Detailed Description |

DRS | Series Name | Demag Wheel Block System |

160 | Size/Scale | The size of the block refers to the wheel diameter. |

A45 | Wheel Shape | A type wheel (double-flanged); 45 refers to the tread width or specific material profile. |

B | Wheel Material | Usually represents Spheroidal Graphite Cast Iron (GGG 70), known for self-lubricating and high wear-resistance properties. |

0 | Connection Type | Refers to the interface type between the wheel block and the drive unit. |

18B | Spline/Bearing Spec | Represents the internal bearing dimensions or transmission spline parameters. |

H | Mounting Position | Horizontal installation or a specific factory configuration marking. |

A30 | Accessories/Options | May involve surface treatment, protection class, or specific flange/bracket fittings. |

2. Core Advantages of the Demag DRS Series

Modular Design: The hallmark of the DRS system is its "Plug & Play" capability. It is versatile enough for cranes, transfer carriages, warehouse racking, and telescopic platforms.

High Load Capacity: At standard speeds, the DRS 160 size can support several tons per wheel, depending on the travel speed and rail material.

Maintenance-Free Characteristics: Equipped with high-performance bearings and self-lubricating wheel materials (such as the "B" material mentioned above), it significantly reduces rail wear and operating noise.

Superior Alignment Precision: The housing features five machined mounting surfaces, ensuring precise alignment during installation and preventing abnormal wear caused by eccentricity.

3. Application Recommendations

This specific model is commonly paired with Demag Offset Geared Motors.

Maintenance/Replacement: If you are replacing an existing unit, double-check the wheel tread shape. Type A is double-flanged, whereas Type NA is a flat tread without flanges.

Installation Note: The DRS-160 is a mid-sized unit. Ensure the flatness of the supporting structure during installation to fully leverage its quiet operation and long service life.

Are you looking to replace an old wheel block, or are you currently designing a new equipment system? If this is for a new design, I can provide further assistance regarding the maximum permissible wheel load (wheel pressure) calculations.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.