Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

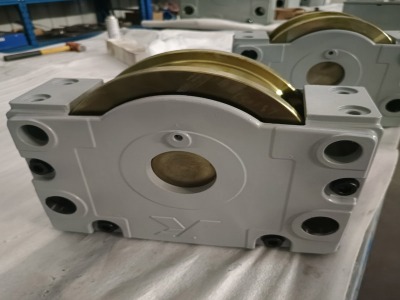

DRS Wheel Block is a modular travel wheel system. Unlike traditional separate wheel and bearing housing arrangements, it features a standardized, integrated design that combines the wheel, bearings, and housing into a single unit. It is typically mounted directly onto the end carriages or trolley frames via bolting or welding.

Core Components:

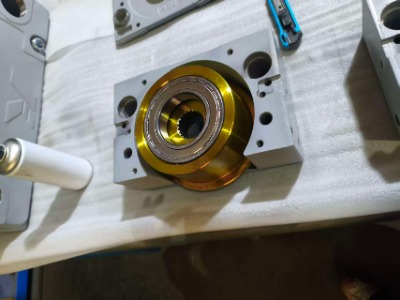

The Wheel: Usually forged or cast from high-strength alloy steel (such as 42CrMo), with the tread induction hardened for superior wear resistance.

Bearings: High-load spherical roller bearings designed to absorb both radial and axial loads.

Housing: A rigid enclosure that protects internal components and provides standardized mounting interfaces.

Drive Interface: Pre-engineered splined shafts or keyways for direct connection to geared motors.

Key Applications in Overhead Cranes

A. Bridge Travel (Main Travel)

On the end carriages of the crane bridge, wheel blocks support the entire dead weight of the crane plus the rated load.

Self-alignment: High-quality wheel blocks offer minor adjustment capabilities to compensate for rail installation tolerances or misalignments.

Load Distribution: Modern cranes often use 4, 8, or more wheels. Wheel blocks allow for a balanced distribution of immense loads across the building's runway rails.

B. Trolley Travel (Cross Travel)

On double-girder trolleys, wheel blocks carry the hoisting machinery as it moves horizontally across the bridge.

Compact Design: The modular nature of wheel blocks saves space, allowing the trolley to travel closer to the ends of the girders, thereby maximizing the crane's working envelope.

Feature | Traditional Separate Wheel Sets | Modular Wheel Blocks |

Installation | Requires precise on-site alignment; labor-intensive. | Plug-and-play; fast positioning via standardized holes. |

Maintenance | Complex; often requires dismantling the end carriage. | Unit replacement; significantly reduces downtime. |

Reliability | Open to contamination; inconsistent service life. | Sealed & Pre-lubricated; protected from dust and debris. |

Aesthetics | Bulky with many exposed parts. | Compact & Integrated; modern industrial design. |

Key Performance Parameters

1. Load Capacity: Maximum wheel load of 16 tons. (This belongs to the "heavy-duty" category within the DRS series, making it suitable for large stacker cranes and overhead cranes).

2. Housing Material: Constructed from GGG70 spheroidal graphite cast iron (ductile iron). Offering high toughness and impact resistance, it is superior to aluminum housings for harsh industrial environments involving high temperatures, heavy dust, and extreme loads.

3. Bearing Configuration: Equipped with standard tapered roller bearings (capable of supporting both radial and axial loads). Features a "Lubricated for Life" design to significantly reduce routine maintenance frequency.

4. Maintenance Accessibility: Features an asymmetrical housing design. This allows for the replacement of the travel wheel or bearings without fully dismantling the housing, minimizing equipment downtime.

Primary Application Scenarios

1. Automated Warehousing: Serves as the travel mechanism for stacker cranes, supporting high-speed and precise movement (speeds up to 240 m/min) between storage racks for efficient cargo handling.

2. Heavy-Duty Cranes: Used in the wheel assemblies of overhead and gantry cranes. It bears the combined weight of the hook and cargo (e.g., in 40-ton class cranes) to ensure stable operation.

3. Mining and Ports: In the travel systems of mining cars and port container cranes, the DRS series can withstand harsh conditions such as rough rails and frequent start-stop cycles, effectively reducing wheel wear.

Contact our technical team today for a customized DRS Wheel Block quote. [Get a Quote]

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.