Shiyang, a premier manufacturer of industrial wheel block systems, has reached a new milestone with the successful export of its DRS wheel blocks to Australia. This delivery, featuring both driven and non-driven DRS-M units, reinforces Shiyang’s position as a trusted global supplier in the material handling and crane component industry.

Why Shiyang’s Export to Australia Matters

Australia is known for its stringent industrial standards, particularly in the mining, manufacturing, and logistics sectors. Shiyang’s ability to penetrate this market is a testament to:

Precision Engineering: Meeting exact technical specifications for heavy-duty applications.

Quality Assurance: Compliance with international safety and durability standards.

Global Reliability: Proving that Shiyang can support complex infrastructure projects across the Oceania region.

Product Spotlight: DRS-M-125 Wheel Block Technical Specs

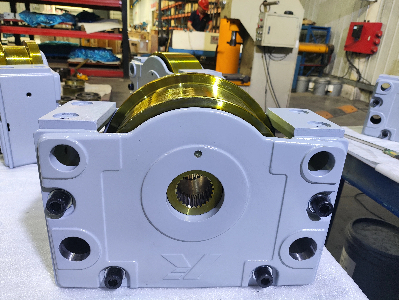

One of the key components in this shipment was the DRS-M-125-A35-D-47-W1-H-W30 (Driven). This model is engineered for high performance in demanding environments.

Feature | Specification |

Max Load Capacity | 5 Tons |

Wheel Diameter | 125 mm |

Wheel Width | 80 mm |

Wheel Material | EN-GJS-700-2 (Ductile Iron) |

Flange Type | One-sided Flange |

Mounting Style | Side-mounted (H-Beam Compatible) |

The Benefits of Integrating DRS Wheel Blocks with H-Beam Structures

Shiyang’s Demag-type travel wheel blocks are specifically designed for seamless integration with H-shaped steel beams, commonly used in crane end carriages and gantry cranes.

1. Modular & Compact Design

The modular nature of the DRS system allows for a compact fit within H-beam structures, saving valuable space while maintaining structural integrity.

2. Rapid Installation

The side-mounting configuration simplifies the alignment process, significantly reducing assembly time on pre-welded or pre-drilled beam flanges.

3. Superior Load Distribution

These wheel blocks are engineered to distribute heavy crane loads evenly across the rails, preventing beam deformation and ensuring a longer lifespan for the entire crane system.

4. Low Maintenance & Smooth Travel

Utilizing high-grade EN-GJS-700-2 material and precision machining, Shiyang wheels offer low-friction travel and high endurance under repetitive stress.

Shiyang: Your Trusted Partner for Customized Wheel Solutions

With decades of expertise in travel wheel block manufacturing, Shiyang goes beyond off-the-shelf products. We offer comprehensive services including:

Custom Manufacturing: Processing based on customer-supplied drawings (OEM/ODM).

Technical Design: In-house R&D for Demag-compatible and bespoke wheel systems.

Specialized Treatments: Material selection and heat treatment optimized for specific load, environment, and travel speeds.

Global Logistics: Proven track record of exporting to Tanzania, Libya, Ethiopia, Indonesia, and now Australia.

Conclusion

The export of DRS wheel blocks to Australia highlights Shiyang’s technical strength and "customer-first" philosophy. Whether you are retrofitting an existing crane or manufacturing new material handling equipment, Shiyang provides the precision and reliability your project demands.

[Contact Shiyang today] for a customized quote or to discuss your project’s technical requirements with our engineering team.