Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Shiyang offers high-performance heavy-duty wheel blocks engineered for seamless integration into transfer carts, automation systems, and heavy machinery. Designed to meet the rigorous standards of the Demag DRS system, our wheel components provide exceptional reliability for industries such as shipbuilding, steel production, and smart logistics.

Key Components & Technical Excellence

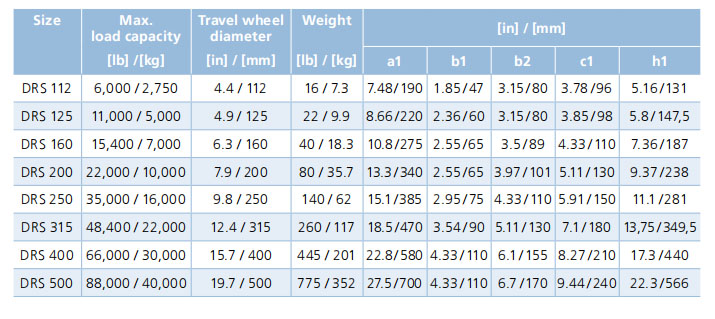

High-Durability Wheels: Available in high-strength steel or wear-resistant polyurethane. We offer 8 different wheel profiles to fit flat or flanged tracks, supporting heavy loads from 2.47t to 40t.

Rugged Housing: Crafted from high-grade steel, our compact housings protect internal components from dust and moisture. With 4 flexible mounting methods, they integrate easily into any mechanical structure.

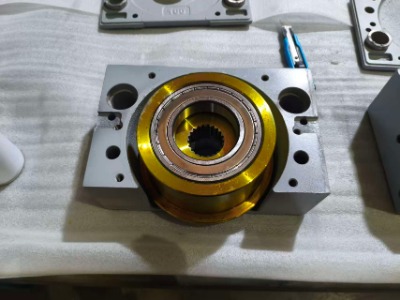

Precision Bearings: Equipped with advanced sealing systems to handle both axial and radial loads, ensuring maintenance-free operation and long-term energy efficiency.

Integrated Drive Units (Optional): Supports automated operations with high-torque motors and efficient gearboxes for precise speed and direction control.

The Main Advantages of Demag Heavy-duty Wheel Blocks

• High performance: Excellent load-bearing capacity ensures reliable operation in industrial environments.

• Versatility: Suitable for a variety of transfer trolleys, automation systems, and other heavy-duty applications.

• Durability: Long service life is achieved even in harsh conditions such as corrosive, dusty, or high-temperature environments.

• Easy integration: Compact modular design facilitates quick installation and replacement.

• Low maintenance: Advanced sealing and lubrication systems minimize downtime and maintenance costs.

Shiyang is a reliable manufacturer integrating design, production, testing, and after-sales. If you have relevant needs, you can contact us at any time.

DRS-125-A45-D-65-K-X-A30 wheel block features high-strength GGG 70 spheroidal graphite cast iron construction to the flexible K-type top connection.

The DRS Wheel Block System is a versatile, high-performance travel unit designed to provide seamless movement for cranes, transfer carriages, and industrial moving structures.

The DRS 315-A65-B-0-8-H-W50 is a high-performance modular wheel solution that integrates precision engineering, high load capacity, and seamless drive integration.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.