Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

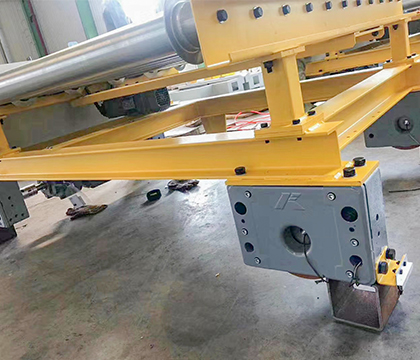

AGV wheel block systems are versatile components used in various applications, typically in material handling or transportation systems. They can be configured in different ways to support loads, facilitate movement, or provide stability.

1. System Overview & Design Philosophy

AGV Wheel Block Systems (such as the versatile DRS series) are modular components engineered to support loads, facilitate precise movement, and ensure stability in demanding environments.

Modular Architecture: The system features a plug-and-play design that allows for rapid assembly, disassembly, and seamless customization.

Core Applications: While primarily designed for Automated Guided Vehicles (AGVs), these systems are also essential for high-performance conveyor setups and heavy industrial machinery.

2. The PU-Coated Advantage

Integrating Polyurethane (PU) coatings into wheel block systems offers significant performance upgrades over traditional steel wheels:

Feature | Technical Benefit | Impact on Operations |

Noise Reduction | PU absorbs friction and vibration more effectively than metal. | Creates a quieter, safer environment for warehouse personnel. |

Floor Protection | The elastic nature of PU prevents scuffing and scratching. | Preserves expensive facility flooring and reduces maintenance. |

Shock Absorption | Inherent damping properties cushion the vehicle against bumps. | Protects sensitive onboard electronics and fragile cargo. |

Durability | High resistance to wear and abrasion during continuous use. | Extends the service life and lowers the Total Cost of Ownership (TCO). |

Corrosion Resistance | Naturally rust-proof and resistant to moisture/chemicals. | Ideal for cleanrooms, chemical plants, or humid environments. |

Custom Flexibility | Customizable hardness levels (durometer) and tread patterns. | Optimized traction and grip for specific floor types. |

3. Key Industry Applications

AGVs equipped with advanced wheel blocks are revolutionizing workflows across multiple sectors:

Warehousing & Distribution: Optimizing goods-to-person workflows and reducing labor-intensive transport.

Manufacturing: Delivering raw materials to production lines and transporting finished goods with high precision.

Automotive Industry: Facilitating the seamless movement of heavy components between assembly stations.

Cold Chain Logistics: Ensuring reliable mobility for temperature-sensitive products in challenging thermal conditions.

Ready to Optimize Your AGV Performance?" Don’t settle for off-the-shelf components when you can have a tailored mobility solution. With 10+ years of expertise, Shiyang’s engineers are ready to help you select the perfect wheel block system for your unique load requirements and floor conditions.

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

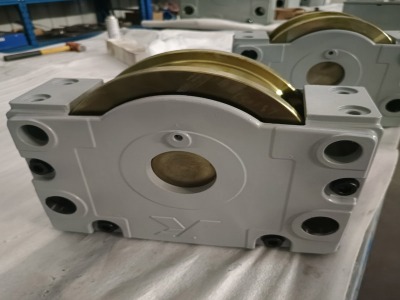

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

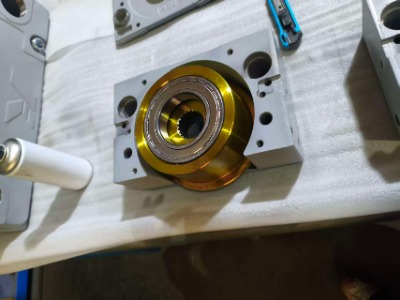

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.