Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

The DRS 250 A65-C-75-B-X-A50 is a premium engineering solution engineered for high-load applications requiring a balance of heavy-duty construction and environmental adaptability. Combining a flangeless design with high-grade Polyamide (Nylon), this model is the industry standard for automated machinery, smart warehousing, and corrosive industrial environments.

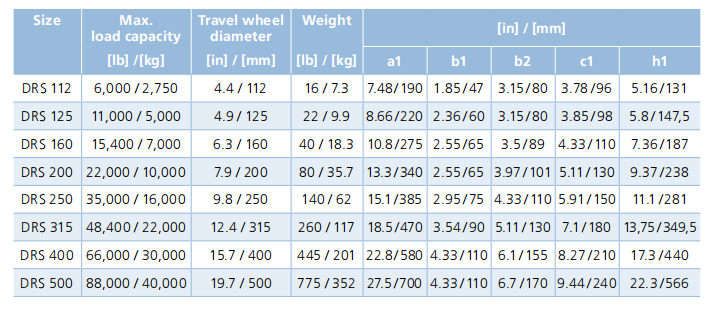

Technical Specifications

Category | Details |

Model Code | DRS 250 A65-C-75-B-X-A50 |

Max Carrying Capacity | 16.000 kg (16 Tons) |

Total Unit Weight | 62.00 kg |

Wheel Material | High-grade Polyamide (C-Type Nylon) |

Installation | Torque bracket with Pin Connection (B) |

Transmission | A50 Offset Gearbox Compatibility |

Guidance System | Non-guided (X-Type) |

Core Advantages of Polyamide (Nylon) Construction

Unlike traditional steel wheels, the Polyamide structure of the DRS 250 offers superior performance in complex operational environments:

1. Superior Load Distribution: With a tensile strength of up to 80 MPa, it ensures uniform weight distribution, significantly extending the service life of shafts and bearings.

2. Corrosion & Chemical Immunity: Completely rust-proof. It is highly resistant to saltwater, acids, and industrial chemicals—ideal for food processing, marine, and pharmaceutical facilities.

3. Noise Reduction & Self-Lubrication: The self-lubricating properties of Nylon reduce friction, leading to lower energy consumption and ultra-quiet operation in noise-sensitive warehouses.

4. Impact Absorption: The elastic modulus of Polyamide allows it to absorb shocks from uneven surfaces, protecting both the equipment and the transported goods.

5. Lightweight Efficiency: 60-70% lighter than steel equivalents, reducing rotational inertia and simplifying the installation process.

The Flangeless Design: Why It Matters

The "X-Type" flangeless configuration provides strategic benefits for modern automated systems:

Debris Resistance: The open-side design prevents the buildup of dust and industrial debris, drastically reducing maintenance intervals.

AGV/AMR Ready: Perfectly suited for Automated Guided Vehicles that utilize external sensors or floor tracks for precision steering.

Simplified Replacement: Features a modular hub design for rapid "plug-and-play" installation.

Industry Applications

The versatility of the DRS 250 makes it a top choice across diverse sectors:

Automotive: Heavy-duty conveyors for engine and chassis assembly.

Food & Beverage: Hygienic, washable components for sterile production lines.

Smart Logistics: High-capacity AGVs and shuttle systems requiring low-maintenance uptime.

Mining & Construction: Reliable material handling in corrosive outdoor environments.

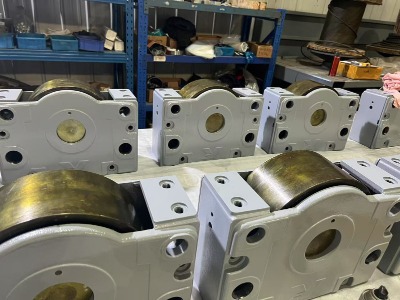

Looking for a reliable Wheel Block System? Contact Shiyang Engineers Today for a Technical Consultation!

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.