Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

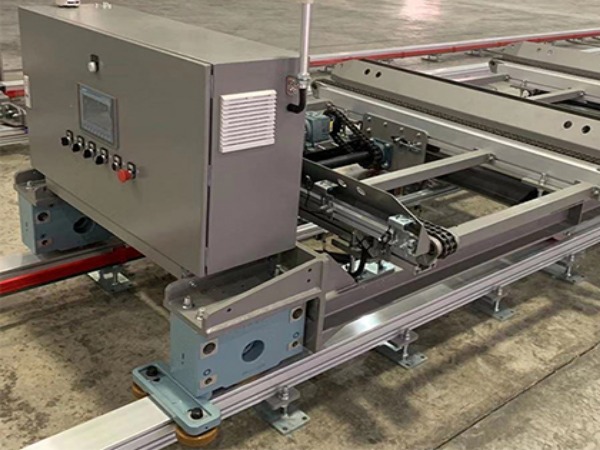

In the fields of automated logistics and heavy equipment manufacturing, the stability of travel mechanisms directly dictates the operational efficiency of the entire production line. Today, we will take a deep dive into a highly representative precision component from the Demag family: the DRS-125-A45-D-65-K-X-A30 wheel block.

I. The Pinnacle of Modular Design: Full Parameter Analysis

This model is not a random combination of letters; it represents a rigorous industrial logic. Based on the technical specification table, it can be broken down as follows:

Base Specification (DRS-125): As the backbone of the DRS series, the 125 size represents a compact structure and reliable load-bearing capacity, meeting the needs of most medium-sized material handling requirements.

Travel Wheel Type (A/D): This model is configured with a Type A (A30/A47) double-flanged wheel, made of high-strength Spheroidal Graphite Cast Iron (GGG 70), designed specifically for rail travel with excellent wear resistance. The Type D designation further indicates a single-flanged wheel configuration for superior guidance.

Connection Structure (K): It utilizes the K (Top) connection method, providing mechanical designers with immense flexibility to easily fix the wheel block to the underside of a support beam.

Configuration Details (X): The X identifier indicates that the unit is not prepared for fitting accessories like horizontal guide rollers, focusing instead on pure, high-efficiency linear travel performance.

Drive Connection (A30): The A interface signifies it is prepared for an offset gearbox connection, with 30 corresponding to the specific flange and shaft dimensions to ensure smooth and stable power transmission.

II. Core Competitive Advantages

1. Material Dictates Longevity

The spheroidal graphite cast iron wheel set used in the DRS-125 not only withstands massive radial loads but also possesses physical properties that protect the rail, reducing maintenance frequency.

2. Precise Rail Matching

Thanks to the optimized combination of flanged wheel designs, this wheel block maintains exceptional centering during high-speed operation, effectively eliminating the common industrial issue of "rail gnawing" (excessive flange wear).

3. Simplified Installation Process

The K-type top connection reduces the installation footprint. Its modular interface design makes replacements and upgrades as simple as playing with "LEGO," significantly shortening equipment downtime.

III. Application Recommendations

The DRS-125-A45-D-65-K-X-A30 is particularly suited for the following sectors:

Automated Warehousing: Travel mechanisms for stacker cranes.

Crane Manufacturing: Serving as the core drive unit for end carriages.

Summary

Ready to Elevate Your Handling Efficiency? Don't let subpar travel mechanisms slow down your production. Contact our technical team today to get the full specifications for the DRS-125-A45-D-65-K-X-A30 and discover how modular excellence can optimize your next project. [Request a Quote Now]

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.