In the modern industrial production system, material handling and transportation systems are core infrastructures that ensure production continuity and improve operational efficiency. Their stability and adaptability directly affect the productivity and safety of the entire production line. In this field, the Demag DRS wheel block system has become a trusted benchmark solution for industrial enterprises worldwide, thanks to its modular design, excellent durability, and ultra-stable and smooth operation performance. As a professional manufacturer specializing in the R&D and production of customized DRS wheel block systems, Shiyang has a deep insight into the material handling pain points in different industries. Relying on a mature technical system and rich engineering experience, Shiyang provides customized services that accurately match load requirements and complex working conditions. This article will comprehensively analyze the customization process of the DRS traveling wheel block system and demonstrate the full-chain professional service capabilities from demand connection to delivery.

I. Why is Customization of DRS Wheel Block System an Industrial Necessity?

Material handling environments in industrial scenarios exhibit significant diversity and complexity: from the transportation of heavy components in automobile manufacturing workshops, high-frequency cargo stacking in warehousing and logistics centers, to operations in harsh environments of special industries such as chemical engineering and semiconductors, the requirements for wheel block systems in terms of load capacity, corrosion resistance, and operation accuracy vary greatly. Standardized wheel blocks often struggle to balance multiple demands such as meeting load requirements, environmental adaptability, and energy conservation and consumption reduction. However, customized DRS wheel block systems can achieve the following core values by accurately matching scenario characteristics: first, improving equipment operation stability and reducing the risk of downtime caused by mismatched components; second, extending the service life of wheel blocks and reducing the frequency of spare parts replacement and maintenance costs; third, optimizing energy consumption performance and reducing power loss through scientific structural design and material selection. Shiyang's customized service is based on this core logic to create scenario-specific wheel block solutions for customers.

II. Analysis of the Full-Process Customization Steps for DRS Wheel Block System

Shiyang has established a closed-loop customization system from demand research to after-sales support. Each link integrates professional technical evaluation and refined management and control to ensure that the final product accurately meets customer needs.

1. Scenario Research and Accurate Demand Definition

The starting point of customization lies in a deep understanding of the application scenario, and this link directly determines the adaptability of subsequent solutions. Shiyang's technical team will clarify core demands through multi-dimensional research: first, the type of equipment application, accurately distinguishing the operating characteristics of different equipment such asoverhead cranes, transfer carts, and gantry systems—for example, the wheel blocks of gantry systems need to bear greater lateral force, while the wheel blocks of transfer carts have higher requirements for ground adaptability; second, core operating parameters, including rated load (single-wheel load and total wheel block load), operating speed, duty cycle (intermittent operation or continuous operation), track specifications and other key data, which are the basic basis for wheel block structural design; third, special environmental requirements, such as working conditions with high temperature, high humidity, high dust, and corrosive gases, which provide a basis for subsequent material selection and protection design.

2. Scientific Specification Selection for DRS Wheel Blocks

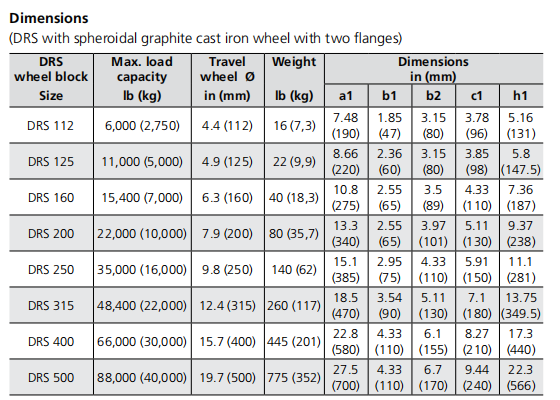

After clarifying the demands, the technical team will conduct specification selection based on the standard system of Demag DRS wheel blocks and optimize parameters in combination with customization requirements. The core of selection focuses on two key indicators: "load-bearing safety" and "operation smoothness": first, matching of wheel diameter and width. Determine the reasonable wheel diameter size according to the calculation formula of load weight and contact area—the greater the load, the larger the wheel diameter needs to be to reduce the pressure per unit area and extend the service life of the wheel block and track; second, preliminary selection of wheel body materials. High-strength steel wheel bodies can be used under normal working conditions. If wear resistance needs to be improved or operating noise reduced, rubber-coated materials such as polyurethane (PU) or nylon can be used. For special corrosive environments, stainless steel materials or surface anti-corrosion treatment can be adopted; third, matching of bearing specifications. Select deep groove ball bearings or self-aligning roller bearings according to operating speed and load characteristics to ensure that the bearing life is synchronized with the overall service life of the wheel block.

3. Personalized Design of Connection Structure

The connection structure is the key to the stable connection between the wheel block and the main equipment. Shiyang provides a variety of connection methods for customers to choose from and can conduct exclusive design according to the equipment interface characteristics. Mainstream connection types include: flange connection, which is rigidly connected to the equipment bracket through a flange plate and is suitable for high-precision operation scenarios with high requirements for concentricity; bushing connection, which adopts a detachable bushing structure for easy later maintenance and replacement, suitable for medium and light load equipment with intermittent operation; customized bracket connection, which designs exclusive connection brackets for non-standard equipment interfaces and achieves stable connection through welding or bolt fixing. During the design process, the technical team will conduct strength checking on the connection structure through finite element analysis (FEA) to ensure sufficient safety factor under extreme loads.

4. Refined Customization of Wheel Body Configuration

Wheel body configuration is the core link of customization. Shiyang meets the special needs of different scenarios through flexible combination of wheel body structure and materials. First, rim structure design. Three options are provided: double rim, single rim and rimless. The double rim structure has stronger guidance and is suitable for curved tracks or operation scenarios with high precision requirements; the rimless structure can reduce operation resistance and is suitable for high-speed operation scenarios on straight tracks. Some rimless wheel blocks can also adopt large-diameter design to improve ground clearance and adapt to uneven ground operations; second, customized wheel bodies with special materials. For cleanroom scenarios (such as semiconductor factories), polyamide (PA) concave wheels without dust shedding can be provided; for flammable and explosive environments, anti-static material wheel bodies can be selected; for shock absorption and noise reduction needs, hydropur hydraulic buffer tires can be customized to effectively absorb impact loads during operation; third, wheel body surface treatment, such as quenching to improve surface hardness, or hot-dip galvanizing and anti-corrosion coating spraying to enhance corrosion resistance.

5. Adaptation and Optimization of Drive System

According to the power transmission method of the equipment, Shiyang provides two drive adaptation solutions to ensure that the wheel block operation perfectly matches the equipment power system. The first is the direct drive input solution, which adopts a cylindrical rotor motor combined with an additional flywheel structure. Its core advantage is a gentle torque curve and stable power output during operation, which is suitable for scenarios with high requirements for operating speed stability; the additional flywheel is arranged close to the offset or right-angle gearbox, which not only optimizes power transmission efficiency but also makes the center of gravity distribution of the drive system more reasonable, reducing vibration during wheel block operation; the second is the coupling connection solution, which uses a high-performance conical rotor brake motor as the power source. This motor has the characteristics of high starting frequency, fast braking response and large braking torque, and is especially suitable for working conditions with frequent start-stop and high requirements for braking precision (such as precise positioning scenarios in automated warehousing). Both solutions support customized adjustment of motor power and reduction ratio to ensure that the power output accurately matches the load requirements.

6. Strengthened Design for Environmental Adaptability

For special working conditions, Shiyang improves the environmental adaptability of the wheel block through multiple protection designs. In terms of surface treatment, for humid and dusty environments, sealed bearings combined with labyrinth seal structures are adopted to effectively prevent moisture and dust from entering the bearing interior; for corrosive environments, fluorocarbon coating is sprayed on the wheel body surface or stainless steel materials are used to enhance corrosion resistance. In terms of customized special components, for high-temperature environments (such as metallurgical workshops), high-temperature resistant bearings and grease are selected to ensure that the wheel block operates normally in environments above 120℃; for cleanroom environments, oil-free lubrication design and non-marking PU material wheel bodies are provided to avoid oil pollution or dust generation during operation; for flammable and explosive environments, explosion-proof motors and explosion-proof bearings are adopted to meet explosion-proof standards such as ATEX or IECEx.

7. Fast Delivery and Full-Cycle Technical Support

Relying on standardized production processes and modular spare parts inventory, Shiyang greatly shortens the delivery cycle of customized products. Regular customized solutions can be produced and delivered within a few weeks; for emergency orders, an expedited production process can be activated to ensure rapid response to customers' equipment upgrading or maintenance needs. After delivery, Shiyang provides comprehensive technical support services: dispatching professional technicians to guide on-site installation of wheel blocks and track alignment to ensure that the installation accuracy meets operation requirements; providing detailed operation and maintenance manuals to clarify key points and cycles of daily maintenance; establishing after-sales service files, conducting regular return visits to customers, and timely solving problems encountered during use to provide guarantee for the long-term stable operation of wheel blocks.

III. Choosing Shiyang: Core Advantages of Customized DRS Wheel Blocks

As a professional customized manufacturer of Demag DRS wheel block systems, Shiyang's core competitiveness is reflected in three aspects: first, technical professionalism. The team has an average of more than 10 years of experience in industrial wheel block design, with a deep understanding of material handling characteristics in different industries, and can quickly provide accurate customized solutions; second, quality controllability. It adopts Demag's original technical standards for production, conducts strict quality inspection on key components, and the finished products undergo multiple inspection procedures such as load testing and operation stability testing; third, comprehensive services. The full-chain service from demand research to after-sales support ensures that customers have no worries during the customization process.

Whether you need to upgrade the wheel block system of existing equipment or customize an exclusive wheel block solution for new equipment, Shiyang can provide a stable and efficient wheel block solution for your industrial material handling system with professional technical capabilities and thoughtful services. Welcome to contact Shiyang for exclusive consultation services and start the full-cycle customization experience from prototype design to mass production. Contact us!