Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

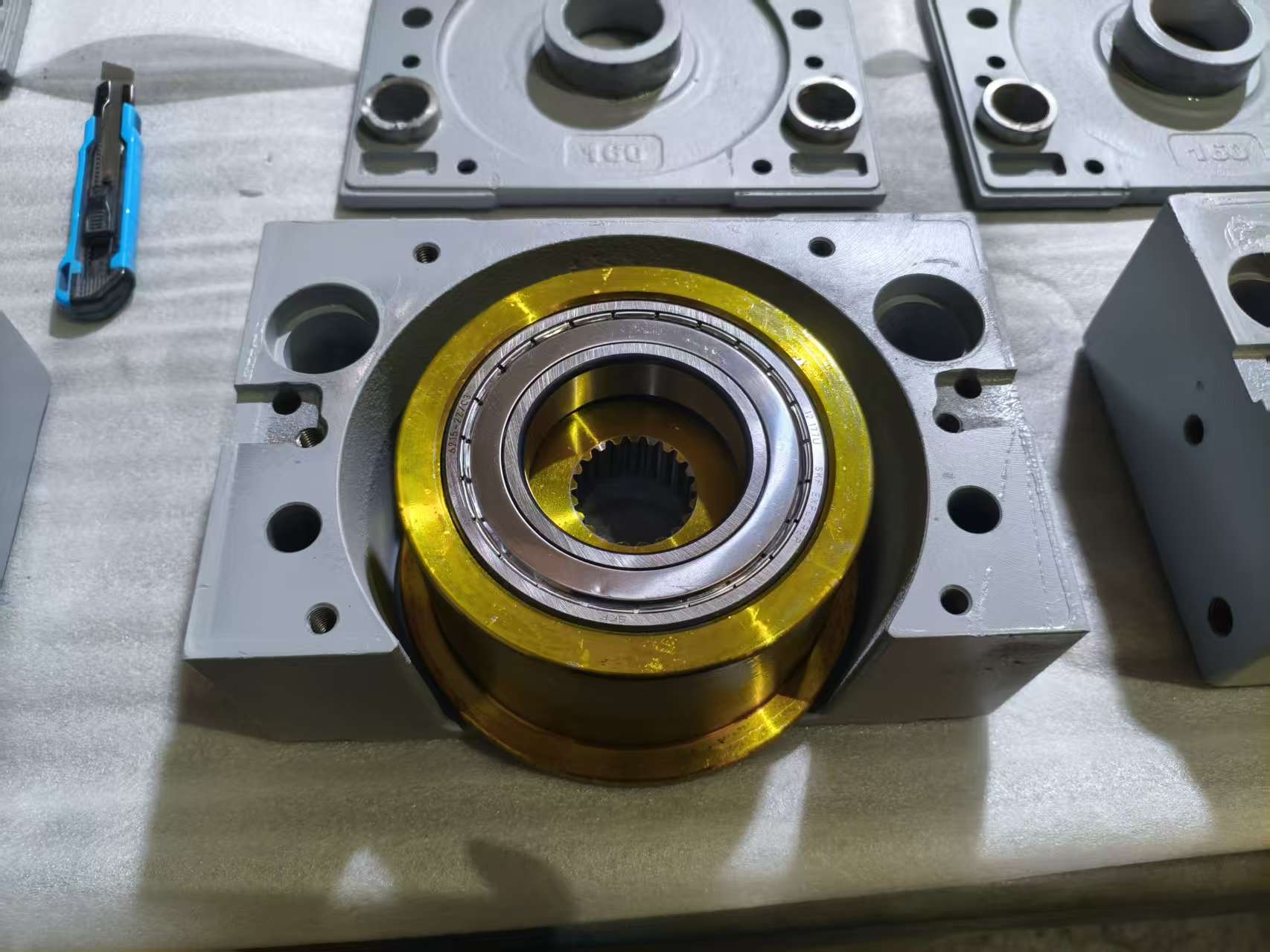

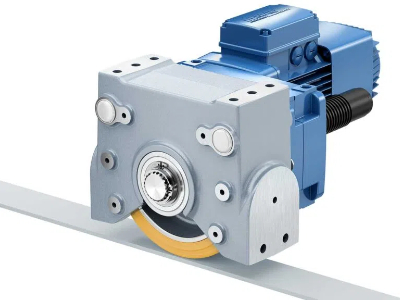

As a core model of Demag’s modular wheel block system, the DRS 250 is deeply aligned with Demag cranes in design and structure. Boasting a 250mm diameter and 16-ton wheel load capacity, it fits Demag crane requirements perfectly and enables direct, modification-free integration into main girder or trolley travel units. Compatible with Demag’s modular drive system, its aligned mounting holes and transmission interfaces cut installation difficulty and risks, ideal for new crane production and aging crane upgrades.

Core Application Scenarios: Covering Diverse Hoisting Working Conditions

Overhead Cranes in Industrial Plants: The Demag DRS 250 delivers stable travel support for Demag overhead cranes in machinery, automotive and metallurgy workshops. Its 16-ton load capacity handles routine heavy lifting tasks with ease, while the high-precision wheel tread ensures tight track contact and steady operation, preventing travel-induced hoisting inaccuracies.

Gantry Cranes in Outdoor Environments: For Demag gantry cranes operating at ports, container yards and building materials warehouses, the DRS 250 fits perfectly into main girder travel mechanisms. Its high-strength wheel material and sealed design resist dust and rain, ensuring stable performance during frequent starts/stops and long-distance travel for heavy-duty operations like container handling and steel stacking.

Supporting Equipment for Special Hoisting Machinery: The DRS 250 also works with Demag stackers, heavy-duty transfer vehicles and other special hoisting equipment. Its compact structure saves installation space, and modular design enables seamless integration with equipment drive systems, ensuring efficient, precise travel control for high-level warehouse storage and heavy component transfer.

Application Advantages: Empowering Efficient Crane Operation

Stable Load-Bearing Capacity with Sufficient Safety Margin: The rated single-wheel load capacity of 16 tons reserves ample safety margin. Even under short-term overloading or unbalanced stress conditions, it can maintain structural stability, complying with the “safety-first” operational requirements of cranes.

High Operational Efficiency and Lower Energy Consumption: The travel wheel adopts an optimized tread curve design, which reasonably distributes the contact area with the track, reducing friction resistance and lowering the energy consumption of the crane drive system. At the same time, the precision bearings and lubrication system inside the wheel block effectively reduce operational noise, improving the comfort of the working environment.

Strong Durability and Low Maintenance Costs: Adhering to Demag’s stringent quality control standards, the core components of the DRS 250 such as the wheel body and bearings are made of high-strength wear-resistant materials, ensuring a long service life. Moreover, its modular design allows for independent disassembly and replacement without the need to fully disassemble the crane travel mechanism, greatly shortening maintenance downtime and reducing later operation and maintenance costs.

Core Supply Scenarios: Covering the Full Life Cycle Needs of Demag Cranes

Our DRS 250 travel wheel blocks can meet the full-scenario supply needs of Demag cranes, from new crane manufacturing to the upgrade of aging equipment.

Supporting Production for New Cranes: We provide supporting travel wheel blocks for Demag crane original equipment manufacturers, serving as core components of the travel units of crane main girders or trolley frames. Relying on precise adaptability and stable performance, it helps complete cranes pass Demag’s original factory quality certification and enhances the competitiveness of complete crane products.

Equipment Upgrade for End Users: For aging Demag cranes with worn-out travel wheel blocks in scenarios such as industrial plants, ports, container yards and logistics warehouses, we offer direct replacement solutions. The upgrade can be quickly completed without modifying end carriages, frames and other structures, restoring the travel stability and load-bearing capacity of the cranes.

Supply of Maintenance Spare Parts: We provide long-term spare parts supply for Demag crane after-sales service providers and end users, shortening the spare parts procurement cycle and reducing equipment downtime maintenance costs. The product warranty period is consistent with that of Demag’s original spare parts, with timely after-sales response to solve the worries of users.

DRS 112-MA30-A-47-K-H-A10 wheel block features modular design, MA30 spline shaft, and A10 gearbox compatibility optimizing industrial mobility in automated warehousing and automotive production lines.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

The DRS 250 A65-C-75-B-X-A50 polyamide flangeless wheel represents a solution designed specifically for applications that require medium-weight construction, corrosion resistance, and adaptability to high-load environments.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.