Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In modern industrial logistics and automated production lines, the stability and modularity of travel mechanisms directly determine the operational efficiency of the entire system. As a benchmark in the material handling industry, Demag's DRS wheel block system has earned global acclaim for its exceptional industrial design. This article takes the core model DRS 112-MA30-A-47-K-H-A10 as an example to deeply analyze the technical logic and application value behind it.

I. Model Decoding: Industrial Intelligence Behind Standardization

The model code represents a precise technical configuration:

Model Segment | Specific Parameter | Technical Meaning | Industrial Value |

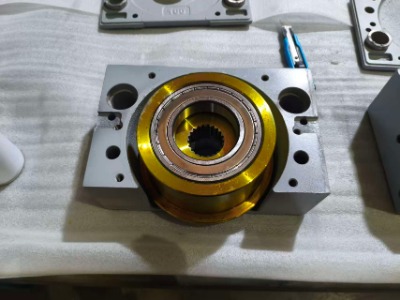

Series/Size | DRS 112 | Wheel diameter of 112 mm | Defines load capacity (max wheel load 2.75t) and installation space. |

Drive Interface | MA30 | Driven type with 30 mm spline shaft | Uses DIN 5480 standard to ensure high-torque, loss-free transmission. |

Wheel Variant | A | Double-flanged spheroidal graphite cast iron wheel (GGG 70) | Provides physical lateral guidance, prevents derailment, and offers self-lubricating properties. |

Tread Width | 47 | Effective tread width of 47 mm | Precisely matches rail width to ensure optimal contact stress distribution. |

Connection | K | Top connection | Simplifies steel structure design; supports rapid bolt-on suspension installation. |

Preparation | H | Prepared for accessories | High flexibility; allows later addition of horizontal guide rollers or track sweepers. |

Gearbox Match | A10 | Compatible with A10 series parallel shaft gearbox motors | Enables "plug-and-play" drive integration and optimizes overall dynamic response. |

II. Core Technical Advantages

1. Highly Efficient Torque Transmission

The MA30 spline shaft design provides a larger contact area and more uniform load distribution compared to traditional keyed shafts. In working conditions involving frequent starts and stops, this design effectively prevents fatigue damage to the shaft end, ensuring long-term stable torque transmission.

2. Superior Materials and Wear Resistance

The travel wheels are made of GGG 70 spheroidal graphite cast iron, a material known for its high load-bearing capacity and excellent self-lubricating characteristics. Combined with the A-47 double-flange design, the wheel block can automatically correct its travel path during operation, significantly reducing rail wear.

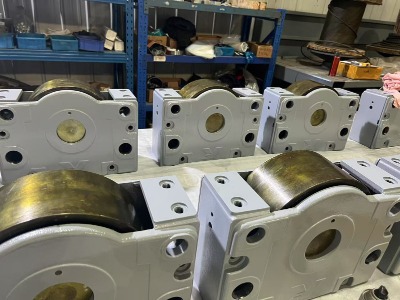

3. Minimalist Modular Installation

The K-type (Top Connection) design allows engineers to fix the wheel block directly under steel structures via bolts, greatly simplifying the assembly process. Meanwhile, the high-quality die-cast aluminum housing reduces dead weight while maintaining strength, enhancing the dynamic response of the entire machine.

III. Typical Application Scenarios

Thanks to the versatile configuration of the DRS 112-MA30-A-47-K-H-A10. it is widely utilized in:

Automated Warehousing: Serving as the core travel unit for shuttles or small stacker cranes.

Automotive Production Lines: Used for mobile workbenches or horizontal transport of heavy materials.

Crane End Carriages: Acting as the travel mechanism core for light-duty single-girder cranes.

IV. Conclusion & Customization

Different industrial environments impose rigorous requirements on travel wheels. Beyond standard models, we provide customization services to meet your specific needs. Whether you require A/D type wheels with special tread widths or wish to upgrade your existing non-driven wheel blocks (NA) to MA-interface driven units, our services cover the full DRS spectrum from DRS 112 to DRS 500. 【Send us your application requirements.】

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.