Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

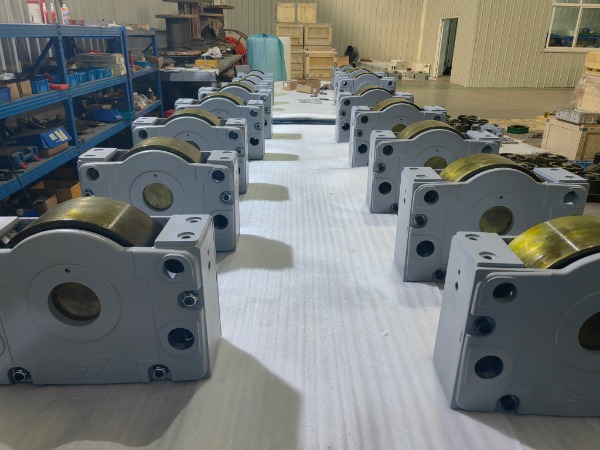

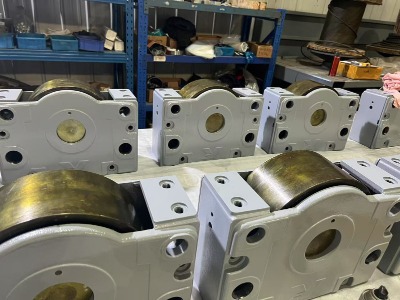

In highly controlled environments such as semiconductor fabrication, pharmaceuticals, biomedicine, and electronics manufacturing, the stability and safety of crane equipment are paramount. Because these industries maintain stringent standards for environmental cleanliness, even minor particle contamination can compromise production quality. Consequently, travel wheel blocks for cleanroom cranes must feature specialized designs and materials to adapt to these rigorous working conditions.

1. Anti-Pollution and Sealed Design

Cleanrooms demand extremely low levels of dust, particles, and pollutants. To meet these requirements, Demag wheel systems typically utilize a sealed modular design:

Physical Barrier: The sealed structure effectively prevents dust, dirt, and tiny particles from entering the wheel block assembly.

Customized Protection: Additional dust-proof accessories can be customized to further reduce the risk of component failure or environmental contamination.

Environmental Maintenance: A high-quality seal ensures that pollutants are not introduced into the cleanroom during crane operations.

2. Low Vibration and Ultra-Quiet Operation

As the core motion drive components of a crane, the vibration and noise control of Demag wheels are critical to maintaining the integrity of the production environment.

High-Precision Components: The system utilizes high-precision bearings, splined hubs, and silent materials to minimize mechanical friction at the source.

Precision Assembly: Components are designed for high-precision assembly to ensure stability and quietness during high-speed operation, preventing interference with sensitive production processes.

3. Oil-Free Lubrication Systems

To eliminate the risk of contamination caused by leaking lubricants or grease, cleanroom drive wheels frequently employ oil-free lubrication technology:

Advanced Material Application: This technology utilizes solid lubricants or specialized dry systems, such as graphite lubrication or polymer coatings.

Maintenance Benefits: Dry lubrication not only prevents the spread of oil contaminants but also ensures long-term smooth operation while reducing the frequency of cleaning and maintenance.

4. Intelligent Monitoring and Predictive Maintenance

Modern Demag wheel blocks can be equipped with intelligent monitoring systems to provide real-time data on operational health:

Multi-Dimensional Monitoring: The system tracks critical parameters in real-time, including temperature, vibration levels, and load status.

Early Warning Signals: If abnormalities are detected, the system sends out early warning signals, allowing operators to perform maintenance or replace parts before a failure impacts production.

Summary

The design, range, and material selection for cleanroom crane wheel blocks must balance multiple specialized needs, including anti-pollution, low noise, corrosion resistance, anti-static properties, and high precision. By integrating sealing technology, precision manufacturing, oil-free lubrication, and intelligent monitoring, these systems ensure stable equipment operation while protecting the cleanliness and quality of the production environment.

Shiyang has consistently focused on the innovation and production of high-quality wheel block systems tailored to the unique requirements of diverse industries. We look forward to discussing your specific project needs—contact us today!

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.