Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Philson heavy-duty wheel block systems in the world of heavy industry and material handling, transport carriages—especially transfer carts—play a pivotal role in moving heavy loads across production lines, workshops, and storage areas. Central to their performance and durability is the travel wheel block system, which must withstand extreme loads, offer smooth mobility, and allow modular adaptability. Philson’s heavy-duty wheel block systems are engineered to meet these rigorous demands across various industrial sectors.

Application scenarios

Wheel block systems are widely used in:

Factory and warehouse logistics for rail-guided transfer carts

Steel plants and foundries where molten metal, heavy castings, or coils must be moved

Automotive and aerospace manufacturing for conveying large components

Shipbuilding yards for moving hull sections and machinery

Cleanroom or semiconductor applications, when equipped with polyurethane wheels to avoid contamination

These transport solutions are designed for precision movement, high-load capacity, and modular integration into a variety of industrial transfer platforms.

Wheel types and travel configurations

To suit different environments and guiding systems, Philson’s wheel block systems offer several wheel shapes:

Double-flange wheels: Ideal for rail guidance, ensuring alignment and preventing derailment.

Single-flange wheels: Common in simpler guide systems where flexibility in alignment is required.

Flangeless wheels with lateral guide rollers: Used in custom track systems with external guide rails, offering minimal rolling resistance and quiet operation.

These options provide flexibility in adapting to different rail conditions, load requirements, and movement precision.

Connection types

Wheel block systems can be connected in multiple ways to suit various cart and carriage structures:

Top connection: Common for mounting under flat surfaces or modular frames.

Pin connection: Allows easy disassembly and maintenance.

End connection: Useful for compact frame integrations.

Side connection: Ideal for applications where lateral mounting is required due to spatial constraints.

This modular mounting design makes wheel blocks easy to install, replace, or upgrade, improving system maintainability and downtime efficiency.

Wheel sizes and load capacities

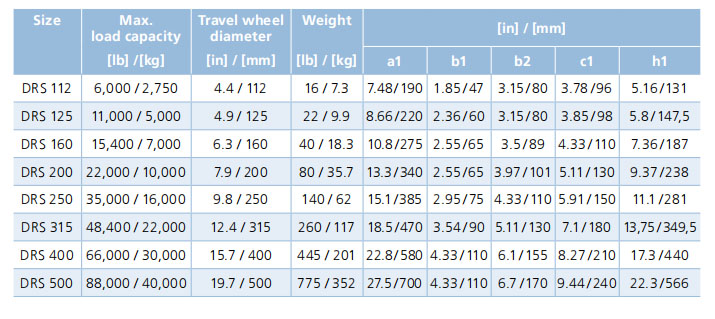

Filson offers a complete range of wheel blocks compatible with DRS type wheels, including:

DRS 112, DRS 125, DRS 160, DRS 200, DRS 250, DRS 315, DRS 400, and DRS 500

Each size is suited for progressively heavier loads, from small AGV systems to massive transfer carts carrying several hundred tons. These wheels are engineered for high-precision rotation, impact resistance, and long service life under continuous operation.

Wheel core materials

Depending on the usage environment, wheel cores are available in:

Forged high manganese wear-resistant steel (40ro): Offers exceptional impact and wear resistance for extreme-duty applications such as steel processing and forging operations.

Spheroidal-graphite cast iron (ggg 70): Excellent for heavy loads with good vibration damping and fatigue resistance.

Polyurethane coating: Ideal for quieter operation and protection of sensitive floor surfaces, often used in cleanrooms or indoor environments.

The choice of wheel material ensures optimal performance whether you’re moving 500 kg or 500 tons.

Driven vs. Non-driven wheels

Wheel block systems can be equipped as:

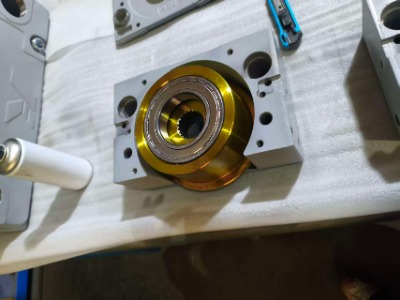

Driven wheels with a spline shaft, integrated into motor-driven systems for autonomous or powered movement.

Non-driven wheels functioning as free-rolling components in passive transport carts.

This split configuration allows integration into various motion systems—rail-guided vehicles (RGVs), automated guided vehicles (AGVs), and more.

Key features and advantages

High load capacity: Engineered to handle extreme weights without deformation.

Modular design: Enables easy replacement and customization.

Versatile mounting: Multiple connection types offer installation flexibility.

Adaptable wheel materials: Suitable for high-friction, shock, or clean environments.

Low maintenance: Precision machining and robust materials reduce service needs.

Philson translation wheel block

Whether you are operating in steel, shipbuilding, automotive, or logistics industries, Philson's heavy-duty wheel block systems for industrial transport carriages deliver reliable, durable, and customizable performance. Designed to integrate with modern transfer carts and automated systems, these wheel blocks are the backbone of efficient material flow in demanding environments.

Contact us today to learn how our travel wheel block systems can enhance the safety, efficiency, and longevity of your heavy-duty transport solutions.

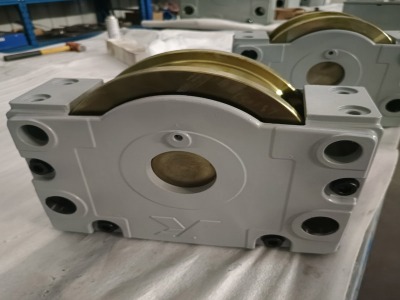

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.