The asymmetric ductile iron housing body is matched with a quenched and forged wheel core. The Chinese manufacturer takes the Demag DRS system as a benchmark and achieves a double breakthrough in technology and performance in the field of heavy-duty travel wheel blocks.

As a professional manufacturer of Demag DRS travel wheel block systems, Shiyang is committed to providing high-quality, reliable, and durable travel wheel block products to global customers and has successfully provided solutions for projects in many countries, such as Tanzania, Libya, and Ethiopia. With the high cost-effectiveness, rigorous process standards, and perfect service system of Chinese manufacturing, we have won the trust and praise of many customers.

Structural design of travel wheel block system

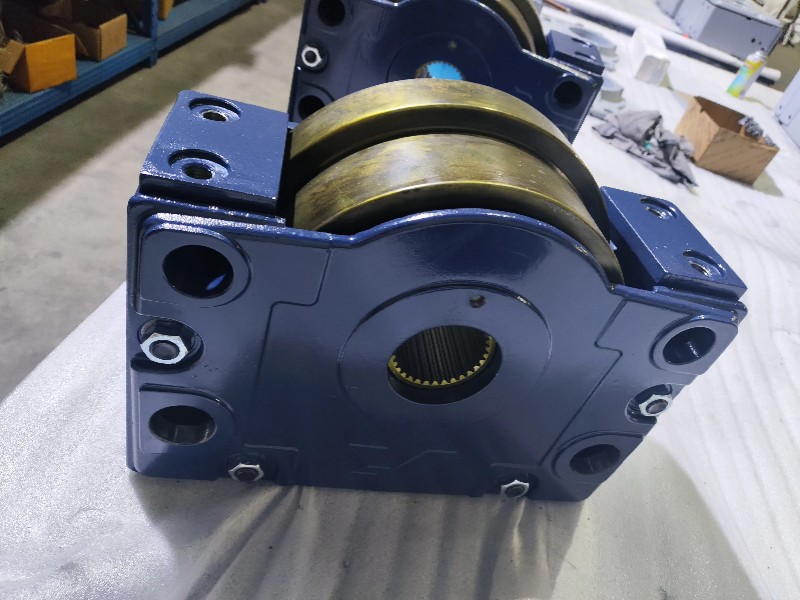

The DRS travel wheel block made in China continues the core architecture of the Demag system and strengthens adaptability in detail:

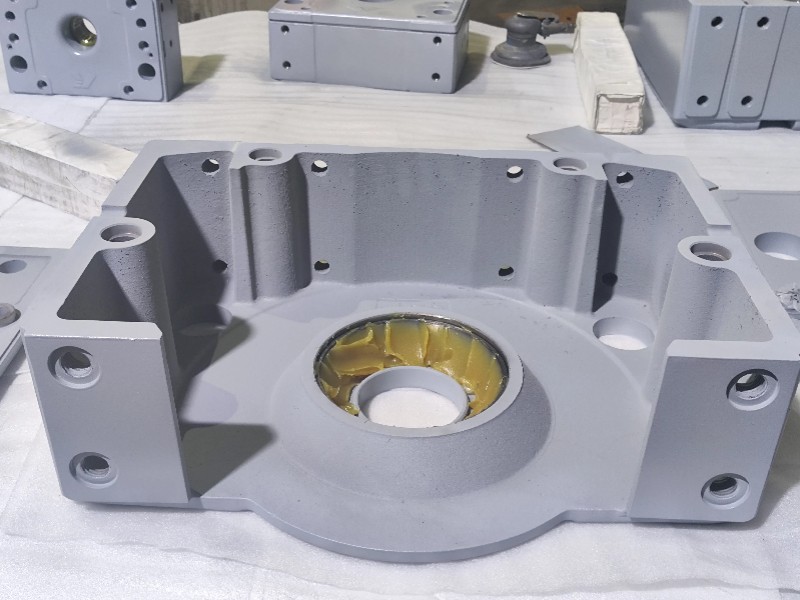

Material upgrade: GGG 70 ductile iron (the same material as Demag) is used, and the asymmetric divisible design is used to achieve rapid replacement of travel wheels without recalibrating the axis position.

Multi-directional installation interface: 4 standard installation spaces are reserved for top (K type), pin connection (B type), end face (S type), and side (W type), which can be directly integrated into the customer's steel structure or hollow profile, and support lateral fine-tuning after installation.

At the same time, sufficient grease has been applied to the key parts inside the housing in advance to ensure the smooth operation of the intelligent drive system and extend the service life of the equipment.

High-performance wheel core design

Our wheel core adopts ductile iron forging and quenching process, with high strength and good wear resistance, and provides a variety of structural options according to the use scenario:

Double-flange wheel core

Single-flange wheel core

Flangeless wheel core can be equipped with a guide wheel set

Polyurethane-coated wheel core (suitable for reducing noise and improving wear resistance)

All wheel cores are treated with anti-rust oil coating, and more than 10 spline types are provided for customers to choose from, suitable for different types of equipment and needs, to ensure efficient transmission and safe operation.

The wheel core is forged and quenched, and the spline strictly complies with industry and national standards to ensure precise meshing with the hollow shaft of the reduction motor and zero deviation in torque transmission.

Strict manufacturing and quality control

In the manufacturing process of the travel wheel block, Philson always adheres to strict process standards:

Painting process: Make sure that each side is completely dry after spraying before spraying the other side, effectively avoiding paint damage or paint loss during the flipping process.

Installation position protection: During spraying, all installation holes are sealed with special plugs to prevent paint or foreign objects from entering, ensuring smooth subsequent installation.

Each process is strictly tested and quality-controlled to ensure that all products shipped meet international quality standards.

Global service and support

In the field of heavy industrial handling, the Demag DRS wheel block system has long occupied the technological commanding heights. Its modular design, single wheel load capacity of up to 2.75-40 tons (DRS112-500 model), and diversified wheel configuration have become the "joint" level components of global cranes, aisle stackers, and intelligent logistics equipment. Today, Chinese manufacturers represented by Philson are pushing this high-end product to a wider global market through localized innovation and strict process control.

As a Chinese wheel block manufacturer, Philson has provided wheel block systems to many African countries, such as Tanzania, Libya, Ethiopia, etc., with its low-price, high-quality, and low-maintenance product advantages, and has been highly praised by customers. We not only provide standard products, but also customize solutions according to customer needs to help your equipment run more efficiently and stably.

If you need to know more product information or get a quote, please feel free to contact us! Philson looks forward to being your trusted partner and escorting your project.