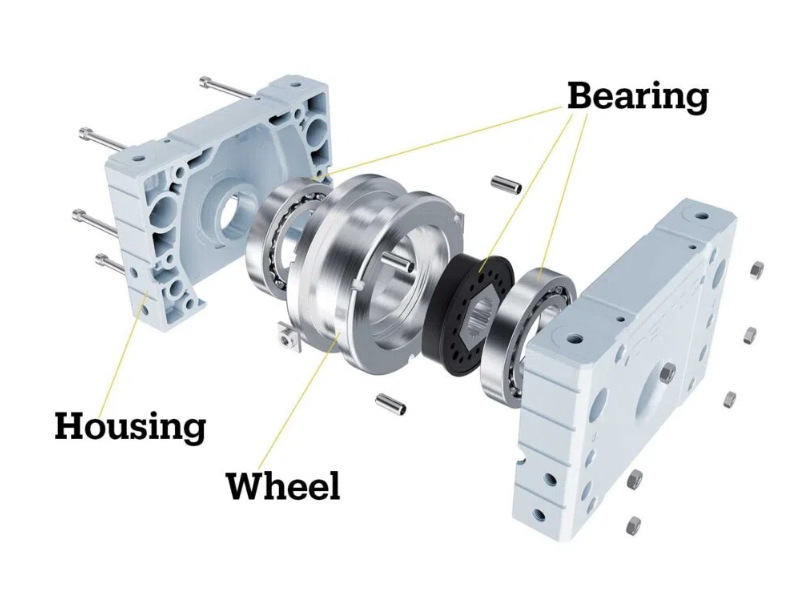

The Demag hollow shaft wheel set is a highly integrated drive system that combines the drive motor, reducer, and travel wheel into a single unit. It employs a hollow shaft connection design, where the motor output shaft is directly inserted into the hollow shaft of the reducer or wheel block. A keyless connection is established using components such as tensioning discs, eliminating the need for traditional complex transmission elements like couplings and keyways. This design simplifies installation and enhances operational stability. Thanks to its compact structure, high transmission efficiency, and ease of installation, it is widely used in rail transport vehicles, overhead cranes, automated conveying platforms, and other applications. It is a core component for improving the stability and reliability of rail-based travel systems.

Why choose a Hollow Shaft Structure?

1. Simple structure and convenient installation

The hollow shaft structure eliminates intermediate transmission components such as couplings and bearing seats, reduces failure points, reduces installation complexity, and facilitates maintenance and replacement.

2. Higher transmission efficiency

The hollow shaft connection structure has good rigidity, high torque transmission efficiency, low operating vibration, and low noise, and is especially suitable for automated rail systems that require precise operation.

3. Save installation space

Since the motor can be directly inserted into the wheel box, the entire drive unit is more compact and adapts to narrow installation spaces. It is an ideal choice for low-profile equipment such as rail transport vehicles, AGV/RGV, etc.

4. High adaptability

It can be applied to motors of various brands (such as SEW, ABB, Nord), with good versatility and flexibility.

Technical advantages of DEMAG Travel Wheel Block System

Demag wheel set combines high-precision processing with modular design concepts, and has the following significant advantages:

• High-strength cast steel structure, strong load-bearing capacity, impact resistance, and long life;

• Maintenance-free bearing system, adaptable to heavy load and high-frequency operation scenarios;

• Modular wheel set design, easy to replace and expand the system quickly;

• Surface hardening or polyurethane rubber wheels are optional to meet the requirements of different ground materials (rails, concrete floors, etc.);

• With the variable frequency drive system, it runs more smoothly and achieves stepless speed regulation.

• It can be customized according to the size of the transport platform, running speed, and track gauge requirements.

Recommended Application Scenarios

• Intelligent stereoscopic warehouse railcar

• RGV/AGV automatic transport platform

• Steel plant/aluminum plant cross-plant railcar

• Automatic stacker and reclaimer

• Heavy-duty mobile devices such as suspension conveying equipment

In the field of material rail transportation, the requirements for "high reliability, low maintenance, and high precision" are becoming more and more stringent. Hollow shaft wheel block with its structural innovation and application stability, provides efficient and reliable travel solutions for rail transportation systems. If you are looking for wheel set products that can improve the performance of the drive system, you may wish to learn about and choose Demag hollow shaft wheel sets to protect your logistics automation system.