Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

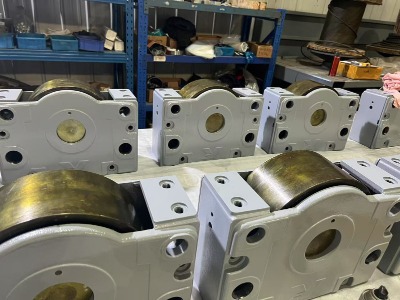

In the field of modern industrial lifting and material handling, the Demag motorised wheel block system serves as a key driving component, widely used in various demanding applications thanks to its outstanding performance and reliability. The system not only handles the long-distance horizontal movement of heavy loads but also achieves smooth, precise, and efficient operation through innovative designs such as the spline gear drive shaft, making it an ideal solution for diverse scenarios ranging from manufacturing workshops to construction sites.

I. The Core Role of the Wheel Block System in Crane

The wheel block system in the crane’s travel mechanism directly determines the machine’s stability and positioning accuracy along the track. Integrating travel wheels, axle assemblies, and drive mechanisms, it is fundamental to the safe and efficient operation of overhead cranes and ground-based rail cranes.

As a leading manufacturer in the lifting industry, Shiyang has introduced a wheel block system with an advanced structural design, featuring optimized load distribution, extremely low wear rates, and an extended service life. The system supports various crane configurations and can adapt to high-load and extreme operating conditions. The current DRS series offers wheel diameters ranging from 112mm to 500mm, with load capacities from 2.75 to 40 tons, meeting the needs of different applications.

II. Spline Shaft Wheel Block: The Core of Efficient Power Transmission

A standout feature of the Demag wheel block system is its spline gear drive shaft design. This shaft efficiently transmits motor torque to the travel wheels through a splined engagement structure. Compared to traditional smooth shafts or key connections, the spline connection offers a tighter fit and higher rigidity, effectively reducing transmission slippage and power loss, resulting in smoother operation and significantly improved energy efficiency.

The tooth profile of the spline transmission ensures more even stress distribution, greatly reducing the risk of localized wear. This design not only extends the system’s service life but also enables it to withstand higher operational loads, thereby reducing maintenance frequency and lowering lifecycle operating costs.

III. Key Advantages of the Demag Wheel Block System

High-Efficiency Transmission: The spline gear drive ensures lossless power transfer, providing quicker response and significantly reduced energy consumption.

Exceptional Durability: The rigid modular heavy-duty design resists combined challenges of high loads, high wear, and harsh environments.

Precise Control: Enables millimeter-level positioning accuracy, ensuring safe and reliable handling of heavy loads.

High Customizability: The system can be flexibly configured to meet specific operational needs across different industries.

Conclusion

The Demag wheel block system with an integrated spline gear drive shaft represents a significant advancement in industrial crane travel drive technology. By comprehensively enhancing operational efficiency, durability, and control precision, Demag continues to provide innovative solutions for global customers, helping businesses optimize material handling processes and achieve cost reduction and efficiency improvement.

Contact our expert team now for free technical consultation and project proposals!

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.