Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In the process of modern automobile manufacturing, the automation level of the production line is constantly improving. As a key material conveying tool, the conveyor belt system undertakes the task of efficiently flowing car bodies, parts, and components between different processes. Among them, the wheel block system, as the core component of the conveying system, provides a solid guarantee for the efficient and stable operation of the automobile manufacturing industry with its superior load-bearing performance and structural design.

The role of the wheel block in the conveyor belt system

In the stamping, welding, spraying, assembly, and other links of automobile manufacturing, the conveyor belt needs to operate continuously for a long time, which puts forward high reliability requirements for the drive system. As the "load-bearing and operating unit" in the conveying system, the wheel block mainly plays the following roles:

Carrying the weight of the conveying device and materials ensures the stable operation of the system.

Achieving precise movement of the conveying equipment to meet the positioning accuracy requirements of the production line;

Adapting to complex tracks or multi-directional operation requirements to improve the overall transmission flexibility;

Combining with the motor and reducer to form a drive unit to form a complete power system.

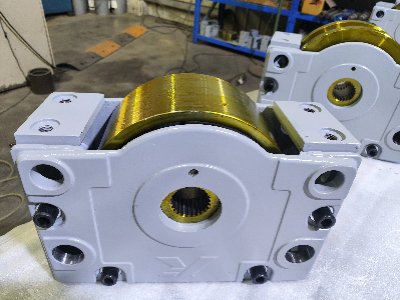

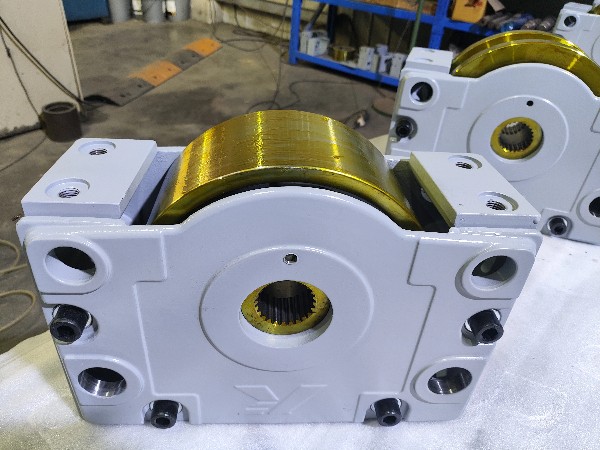

Design features of the Demag wheel block

As the world's leading manufacturer of industrial lifting and transmission equipment, Demag has many advantages in structural design and manufacturing process for its wheel block:

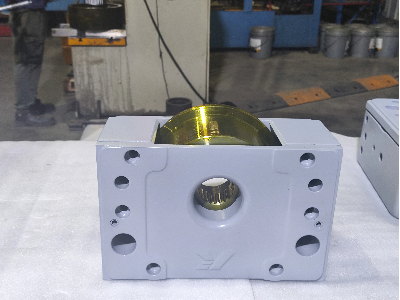

• Modular structure, flexible installation

Demag wheel block adopts a standardized and modular design, a flangeless hub to speed up the conveyor belt, quickly integrates automotive accessories into various conveying structures, supports multiple installation methods (top, pin, end, both sides), and has strong adaptability.

• High load capacity and compact structure

Adopting a high-strength ductile iron shell, equipped with precision-machined bearings and wheel bodies inside, it has a strong load capacity and is particularly suitable for the continuous transportation needs of large and medium-sized workpieces in automobile production lines. The load-bearing capacity ranges from 2.75 to 40 tons.

• Multiple wheel diameters and configurations are available

According to different conveyor line speeds and load-bearing requirements, Demag provides various models and sizes of wheel blocks (such as DRS, LRS, etc.), supporting customized wheel diameters, wheel materials (steel wheels, polyurethane-coated wheels), and other configurations to meet different working conditions.

• Smooth operation and low noise

The high-precision bearings and high-quality wheel materials enable the wheel block to maintain stability, low vibration, and low noise during high-speed operation, which is particularly suitable for automobile factories with high requirements for the working environment.

• Easy-to-maintain design

The wheel body and bearing are easy-to-replace structures, and daily maintenance is simple; the shell surface treatment has strong anti-corrosion performance and is suitable for long-term use.

In the automated assembly line of automobile manufacturing, Demag wheel blocks have become an indispensable core component in the conveyor belt system with their advantages of high load-bearing, modularization, quietness, and stability. It not only improves the conveying efficiency and operating stability, but also effectively reduces the equipment maintenance cost, providing strong support for automobile companies to build an efficient and intelligent manufacturing system.

Demag DRS-M 160 wheel block: 7-ton load capacity for heavy-duty box stacker cranes, ideal for multi-layer stacking & thick-walled/semi-finished boxes, ensuring stable operation & low maintenance.

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.