Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

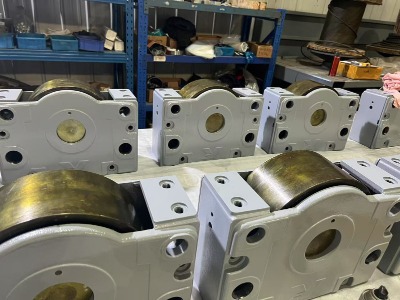

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications. Among its product lineup, the DRS series stands out for its load capacity, structural versatility, and compatibility with a range of motors and drives.

Definition and function of a driven wheel block

A driven wheel block is a type of travel wheel unit that integrates directly with a drive motor. Unlike passive load-bearing wheels, the driven wheel block transfers torque from the motor to the wheel, enabling powered motion across rail tracks or other guiding systems.

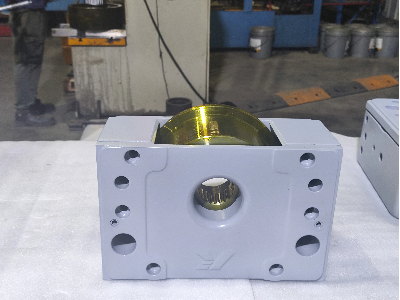

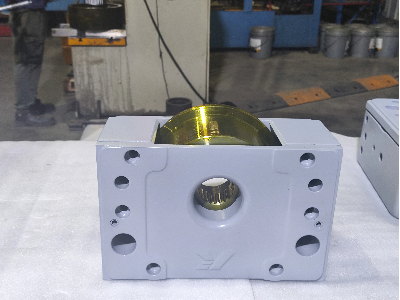

One of the most distinctive features of the driven wheel block is its hollow spline shaft integrated into the wheel core. This design allows for secure and torque-transmitting connections with various drive units. Shiyang, a leading manufacturer, offers more than 10 spline types to meet diverse installation demands across different industries and applications.

![]() Wheel shapes and track adaptability

Wheel shapes and track adaptability

To meet varying environmental and load demands, the travel wheels in driven wheel blocks can be customized in several shapes:

Flangeless wheels with lateral guide rollers – ideal for guided systems requiring smoother turning or curved paths.

Single-flange wheels – used where side guidance is needed on one side only.

Double-flange wheels – provide strong lateral guidance for straight-line travel on rails.

V-shaped wheels – typically used on angle iron tracks or guide rails.

O-shaped wheels – suitable for flat surfaces or grooved tracks

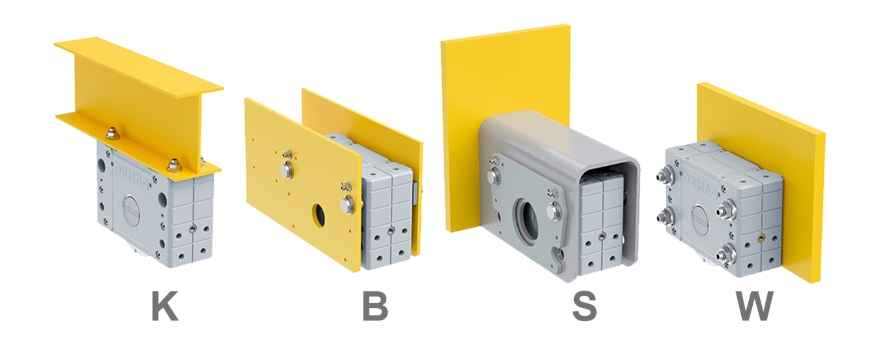

Mounting flexibility: Multiple connection options

Demag driven wheel blocks support four types of connections, allowing engineers to match the best installation method for their application:

Top connection – mounting from above; commonly used in overhead crane systems.

Pin connection – allows pivoting or floating installation to compensate for misalignment.

End connection – ideal for inline or side-mounted applications with horizontal space constraints.

Side connection – suitable for compact arrangements and integrated machine frame installations.

These varied connection options enable seamless integration into existing structures or new equipment designs.

Demag DRS series range and load capacity

The Demag DRS series offers a wide range of models to suit different industrial applications:

DRS 112, 125, 200, 250, 315, 400, 500 – each model is designed for specific load ranges and dimensions.

Custom models – Shiyang can tailor wheel blocks to specific torque, mounting, or load-bearing requirements.

The load capacity of a single driven wheel ranges from 2.75 tons to 40 tons, making the DRS series ideal for high-capacity handling systems in manufacturing, logistics, shipbuilding, and more.

Materials and durability

Shiyang’s driven wheel blocks are manufactured using premium-grade materials to ensure long service life and exceptional load performance:

Housing: Made of spheroidal-graphite cast iron (GGG 70), offering high strength and vibration damping.

Wheels: Available in several material options, including:

Forged high-manganese wear-resistant steel (40ro)

Polyurethane-coated wheels – ideal for noise-sensitive or indoor applications.

Stainless steel wheels – corrosion-resistant for wet or chemically aggressive environments.

Cast iron wheels – robust for heavy-duty industrial use.

Each wheel block assembly includes precision bearings, sealing rings and is optionally self-lubricated to reduce maintenance frequency.

Integrated accessories and drive units

Shiyang not only provides the wheel blocks but also delivers a full drive solution, including:

Sew gear motors

High-efficiency reducers

Couplings and spline shafts

Custom mounting brackets and alignment tools

This full-system approach simplifies sourcing and guarantees mechanical compatibility across all components.

Application scenarios

Demag-type driven wheel blocks are used in a wide array of industrial environments, such as:

Overhead cranes and gantries

Rail-mounted transfer carts

Stacker-reclaimers in mining and ports

Automated storage and retrieval systems (AS RS)

Machine tool carriers and heavy-duty conveyors

Shipyard welding or transport platforms

If you want to customize or learn more about the Demag modular drive system, please contact us at sale10@kfqizhongji.com.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.