Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

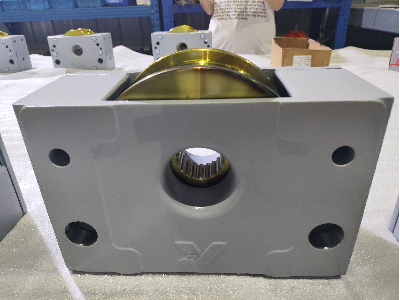

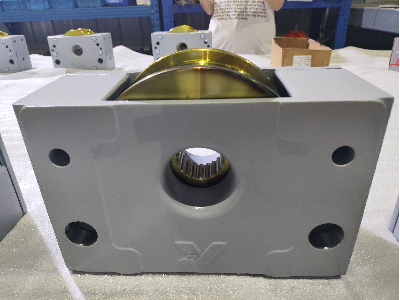

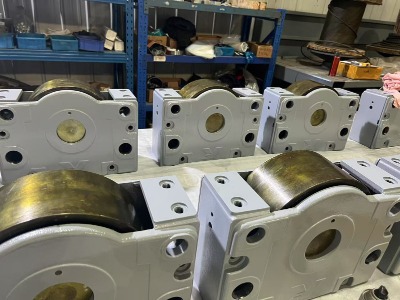

Demag cranes are renowned for their precision engineering and reliable performance in industrial lifting and transport tasks. At the heart of their smooth and efficient operation is the DRS wheel block system, which ensures stable movement and precise positioning of the load. However, over time, the DRS wheel block system may need to be replaced due to mechanical wear, changes in load requirements, or modernization upgrades. Choosing the right replacement system and a reliable manufacturer is essential to maintaining the performance, safety, and service life of the crane.

What is the DRS wheel block system?

The DRS system is a modular wheel block solution developed by Demag for applications requiring precise positioning and controlled movement. These blocks are commonly found in bridge cranes, gantry cranes, and transfer carts.

Key features of the DRS system include a modular design for easy integration, multiple frame sizes for various load requirements, and compatibility with Demag’s modular drive systems. The available wheel block sizes include DRS 112, 125, 160, 200, 250, 315, 400, and 500, covering a wide load range from 2.75 tons to 40 tons.

Reasons for replacing DRS wheel blocks

Replacement may be necessary for several reasons:

Wear and tear: Prolonged operation results in natural wear of wheel surfaces, bearings, and housings.

Load upgrades: Evolving operational demands may require increased capacity.

Damage: Exposure to corrosive environments, misalignment, or overloading can cause wheel failure.

Modernization: Upgrading old crane systems with improved components to meet current performance standards.

Replacement options and compatibility

When considering replacements, users can choose between OEM parts and high-quality third-party alternatives. A reliable replacement must maintain full compatibility with Demag’s drive systems, ensuring smooth integration and operation.

Philson offers replacement DRS wheel blocks with various material options, such as spheroidal-graphite cast iron (GGG 70), wear-resistant steel material 40ro, and polyurethane-coated wheels. Wheel configurations can also be customized, with options including single-flanged, double-flanged, flangeless, and versions with integrated guide rollers to suit various track systems.

Key features of a quality replacement DRS wheel block

A high-performance replacement should offer:

High load capacity: Capable of handling the specified tonnage with smooth travel.

Precision machining: Ensures accurate dimensions and stable mounting.

Corrosion resistance: Protection in wet, chemical, or coastal environments.

Easy installation: Designed to match original Demag dimensions, mounting holes, and connection styles (top, pin, side, end).

Installation and maintenance tips

Safe replacement begins with careful disassembly and alignment of the new wheel block. Correct connection—whether top, side, or pin-mounted—is essential to prevent misalignment and uneven wear.

Routine lubrication, regular inspection of bearings and flanges, and checking for abnormal vibrations help ensure long-term reliability and safety.

Why choose Philson?

Philson stands out with its in-house design, engineering, and machining capabilities tailored for demag system replacements.

Customized solutions: Designed to match or exceed OEM performance.

Heavy-duty experience: Trusted in industries ranging from steel production to logistics.

Fast turnaround: Quick delivery with technical support for installation guidance and follow-up service.

Choosing the right DRS replacement is crucial to maintaining the performance and safety of your Demag crane system. With a focus on quality, compatibility, and custom solutions, Philson offers dependable alternatives for Demag DRS wheel blocks.

Contact us today for a quotation, technical support, or product customization tailored to your crane application needs.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.