Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

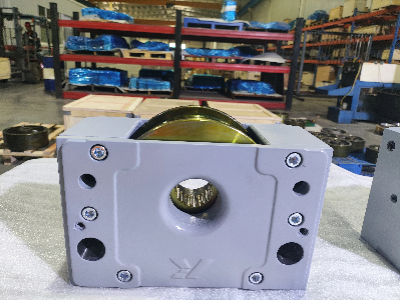

The DRS wheel block is a versatile, multipurpose wheel block system designed to be integrated into various travel units. For a semi-gantry crane—which typically runs on one elevated runway and one floor-level rail—the wheel blocks must handle significant lateral forces and uneven loading.

Key Components:

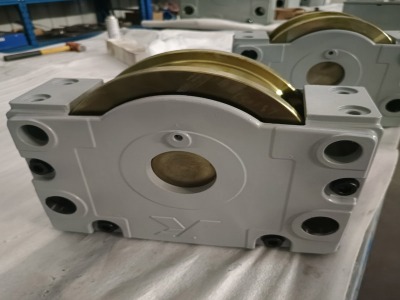

The Housing: A high-quality, impact-resistant aluminum or spheroidal graphite cast iron box that protects the internal bearings.

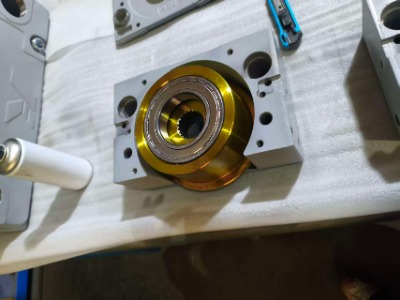

The Wheel: Usually made from nodular graphite cast iron (Spheroidal graphite cast iron) for self-lubricating properties and reduced wear on the rail.

The Bearings: Heavy-duty roller bearings designed to absorb both radial and axial loads.

Why Double Flange for Semi-Gantry Cranes?

In a semi-gantry setup, the "leg" side of the crane travels on a ground rail. This rail is prone to collecting debris or having slight alignment variations.

Superior Guidance: The double flange acts as a "track keeper." With a flange on both sides of the rail head, the wheel is physically prevented from jumping the track, even if the crane experiences a slight "skew" (crabbing) during movement.

Lateral Force Absorption: Semi-gantry cranes often carry asymmetrical loads. The double flange setup provides a mechanical stop against horizontal forces, ensuring the crane stays centered on the floor rail.

Reduced Derailment Risk: Unlike single-flange wheels used in overhead bridges, the double flange is essential for ground-level rails where safety margins for lateral movement are tighter.

Technical Advantages of the DRS System

Feature | Benefit for Semi-Gantry Operations |

Modular Design | Easy to swap out wheels or bearings without dismantling the entire crane leg. |

Spheroidal Graphite Iron | Provides a "damping" effect, reducing noise and vibrations during travel. |

Multiple Mounting Surfaces | Can be bolted to the crane structure from the top, side, or end. |

Spline Connection | The drive shaft uses a spline rather than a simple keyway, providing better torque transmission and easier motor mounting. |

For a semi-gantry crane, using a Double Flange DRS system on the floor rail ensures that the transition between the stiff elevated runway and the more flexible ground travel is seamless. It compensates for the inherent "walking" tendency of long-span cranes and protects your infrastructure from premature wear. Ready for a smoother, more reliable crane performance?Simply let us know your required load capacity and span, and we’ll show you how the DRS Double Flange system provides the ultimate protection for your workshop. Get in touch.

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.