Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

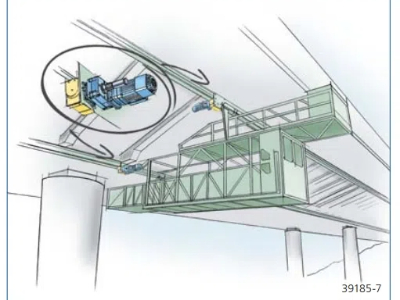

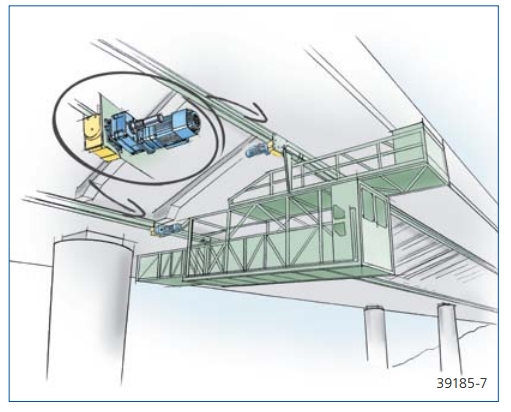

In the landscape of modern material handling, suspension cranes are widely prioritized for their ability to maximize overhead workspace and eliminate the need for floor-mounted support columns. At the heart of these systems, the DRS Wheel Block System has established itself as the industry benchmark for modular, pre-engineered travel units. It is not merely a mechanical component but a strategic solution ensuring high-precision kinematics, structural integrity, and long-term reliability.

1. Modular Architecture and Design Integration

The core competency of the DRS system lies in its modular housing geometry, which offers unparalleled versatility for cranes operating on the lower flange of the runway beam where installation envelopes are often restricted:

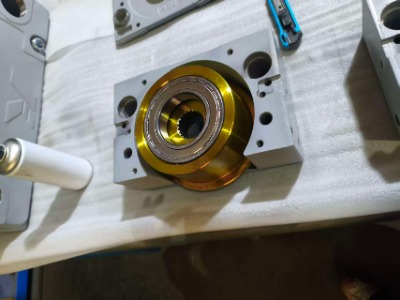

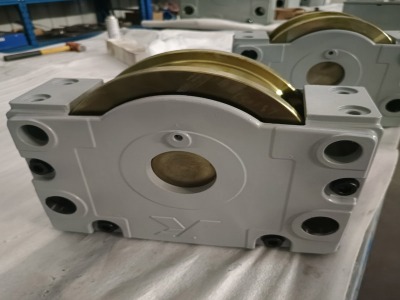

Multi-faceted Mounting Interfaces: The housing is constructed from spheroidal graphite cast iron and precision-machined on five sides. These standardized mounting surfaces and pre-drilled holes allow for direct bolting to crane end carriages or structural members, eliminating the need for costly welding or post-weld alignment.

Integrated Drive Coupling: Utilizing a patented splined profile, the wheel block achieves a high-torque, backlash-free connection with geared motors (typically parallel-shaft or right-angle geared motors). This compact configuration minimizes the lateral "dead zone," thereby optimizing the crane’s approach dimensions and floor coverage.

2. Engineering Optimization for Underslung Applications

Suspension cranes are inherently susceptible to runway misalignment, load-induced oscillations, and flange wear. The DRS system mitigates these technical challenges through:

Vibration Damping & Fatigue Resistance: The use of GGG 70 (ductile iron) provides superior mechanical damping characteristics. This ensures the absorption of dynamic shock loads during travel, protecting the runway superstructure from stress concentrations and fatigue failure.

Optimized Tread Profiles: To accommodate various I-beams or specialized track profiles, DRS wheels are available in multiple geometries. These optimized wheel-to-rail contact geometries distribute Hertzian contact stress evenly, preventing premature rail edge deformation.

Precision Geometric Tolerances: Due to CNC-machined housing accuracy, the system ensures absolute parallelism of the wheel axes. This fundamentally eliminates rail gnawing, reducing rolling resistance and extending the service life of both the wheel and the track.

3. Operational Efficiency and Total Cost of Ownership

The adoption of DRS technology translates into significant economic advantages through optimized Key Performance Indicators:

Low Rolling Resistance: Equipped with high-performance anti-friction bearings and precision-ground treads, the system ensures smooth acceleration/deceleration ramps, lowering energy consumption and cycle times.

"Ready-to-fit" Logic: Delivered as a self-contained, maintenance-free/pre-lubricated unit, the DRS drastically shortens the Time-to-Market during the assembly phase. In the event of an overhaul, the plug-and-play design allows for a rapid replacement of the entire travel unit without structural disassembly.

Environmental Customization: Options such as Protean (polyurethane) treads for non-marking cleanroom applications or specialized high-temperature coatings ensure the system's robustness in extreme industrial environments.

4. Safety and Structural Reliability

In suspension systems, structural security is non-negotiable. The DRS ensures safety through:

Load Bearing Redundancy: With a range spanning from DRS 112 to DRS 500, the system supports wheel loads from 25 kN to 400 kN, maintaining a high safety factor against plastic deformation.

Lateral Guide Integration: Optional lateral guide rollers can be integrated to manage the horizontal forces generated by load swing or eccentric lifting, ensuring the crane remains centered on its kinematic axis.

Conclusion

The DRS Wheel Block System is a cornerstone of precision motion control. By synthesizing modular flexibility with superior mechanical properties, it empowers suspension cranes with a more compact footprint, extended Mean Time Between Failures, and reduced maintenance overhead. In the pursuit of high-performance intralogistics, DRS remains the Gold Standard for drive engineering. Ready to Optimize Your Material Handling Efficiency? [Request a Consultation]

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.