Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In today's demanding industrial environment, unplanned downtime is a primary driver of operational costs. The travel system, the very foundation of an overhead crane's mobility, is critical to avoiding these disruptions. While manufacturers like Demag have set high standards, a new wave of innovation from Chinese engineering is making this reliability more accessible than ever. Companies like Shiyang, a leading Chinese manufacturer of high-performance, compatible wheel block systems, are leveraging modular design to deliver unparalleled value and uptime to a global clientele. So, how does a modular structure fundamentally benefit maintenance? The answer lies in transforming complex, time-consuming repairs into simple, swift replacements.

From Hours to Minutes: The Paradigm Shift in Maintenance

Traditional, monolithic wheel block designs often require extensive disassembly, specialized tools, and significant calibration time when a single component fails. A fault in a bearing could lead to a days-long stoppage.

Modular wheel blocks, like those engineered by Shiyang, are designed as a system of independent, pre-assembled units—such as the drive module, idler module, and connection elements. This approach delivers transformative benefits:

Rapid Diagnosis and Swap-Out: Issues can be isolated to a specific module. Instead of repairing on-site, technicians simply replace the entire module with a pre-calibrated unit. What was once a day-long procedure is reduced to a matter of hours, drastically cutting downtime.

Reduced Skill Barrier and Risk: The replacement process is simplified to basic bolting and electrical connection (for driven units). This minimizes the need for highly specialized technicians on-site and reduces the risk of errors during reassembly.

Optimized Inventory Management: Companies no longer need to stock a vast array of individual components. Instead, maintaining a few key replacement modules on hand ensures readiness without tying up excessive capital in spare parts.

Beyond the Design: The Competitive Edge of Localized Manufacturing

The benefits of modularity are amplified by Shiyang 's position as a leader in Chinese manufacturing.

Cost-Effectiveness without Compromise: By leveraging advanced manufacturing capabilities and a robust local supply chain, we offer compatible wheel block systems that meet rigorous quality standards at a significantly lower Total Cost of Ownership (TCO).

Agility and Customization: Our engineering team excels at providing tailored solutions. We can quickly adapt our modular designs to fit specific rail specifications, environmental conditions, or load requirements, offering a level of flexibility that is often challenging for larger, standardized producers.

Unmatched Responsiveness and Support: With a global logistics network and dedicated, English-speaking technical support, we ensure that our international partners receive the parts and expertise they need, when they need them. This direct line of communication simplifies the supply chain and builds stronger, more responsive partnerships.

Shiyang continues to invest in R&D, integrating smart technology into its modules to pave the way for predictive maintenance and further enhance the intelligence of material handling equipment.

About Our Company :

Shiyang is a premier Chinese manufacturer specializing in the d esign and production of high-quality, compatible travel wheel systems and components for overhead cranes. Committed to innovation, reliability, and customer-centric solutions, the company serves a global clientele across ports, steel, manufacturing, and logistics sectors.

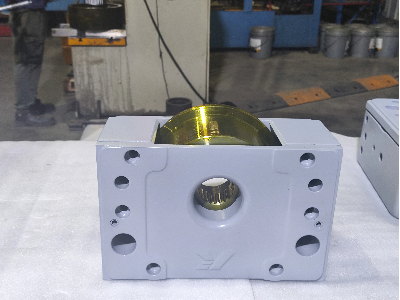

Demag DRS-M 160 wheel block: 7-ton load capacity for heavy-duty box stacker cranes, ideal for multi-layer stacking & thick-walled/semi-finished boxes, ensuring stable operation & low maintenance.

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.