Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Due to its modular design, high load adaptability and intelligent control capabilities, the Demag DRS intelligent drive system has become an ideal choice for heavy-duty systems such as bridge cranes, heavy-duty AGV transfer platforms, gantry cranes, and automated logistics equipment, significantly improving the operating efficiency, accuracy, and reliability of the equipment.

Overview of the DRS Intelligent Drive System.

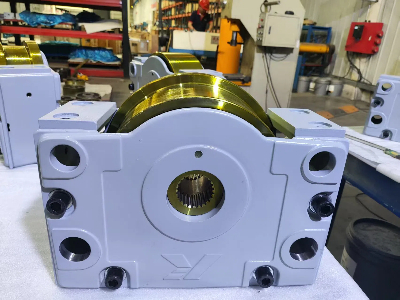

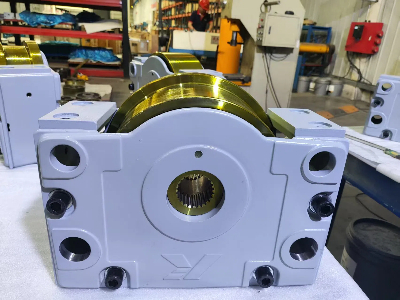

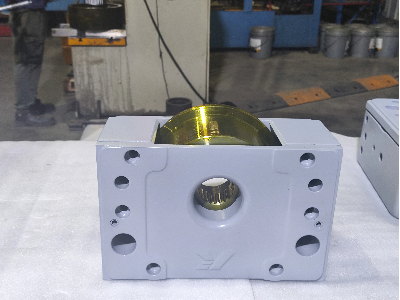

Demag DRS (Drive Running System) is a wheel system with integrated drive, guide, and support functions. It combines precision-machined wheels, load-bearing structures, integrated transmission units, and intelligent control solutions, and is suitable for various heavy-duty and medium- and high-frequency working occasions. It not only has excellent mechanical performance, but also reserves automation upgrades and digital monitoring interfaces. It is a key component of the intelligent upgrade of modern heavy-duty equipment.

Features of Use

● High load capacity and stable operation

The DRS wheel system provides pressure capacities ranging from 2.75 tons to 40 tons. It is particularly suitable for high-load, continuously running equipment such as bridge cranes and large logistics trolleys. The wheels are made of high-strength steel or high-wear-resistant ductile iron, with excellent impact and wear resistance.

● Modular design, flexible layout

All wheel sets adopt a modular structure, which can be flexibly matched with the chassis of different sizes and mounting structures. Optional steering mechanisms, offset mounting flange, elastic coupling, etc., are available to adapt to various specially-shaped structures and running tracks.

● Intelligent control, precise positioning

It can be linked with the inverter and PLC system to realize functions such as running speed adjustment, soft start braking, load monitoring, etc., to provide support for equipment to achieve precise positioning, synchronous operation, and remote control.

● Easy maintenance and long service life

The bearing is a maintenance-free closed structure, the wheel set body is compact and easy to replace, reducing the maintenance cycle and downtime. Lubrication channels and monitoring points are reserved at the connection between the wheel axle and the support frame.

Structural Features

● Integrated wheel structure

The wheel and bearing are pre-installed in the high-precision machined sleeve through a tight fit, and the sleeve is assembled in the support frame. The overall structure is compact and easy to integrate.

● Multiple installation methods

Supports multiple methods, such as side flange installation, vertical lifting, horizontal direct connection, etc., to meet the layout requirements of different walking mechanisms.

● Optional drive unit

Can be matched with a SEW motor to achieve different operating speeds and torque output requirements.

● Intelligent sensing interface

Reserved sensor installation holes, optional wheel pressure monitoring, speed encoder, temperature sensor, to achieve digital monitoring and predictive maintenance of operating status.

Application Case

● Port tire crane (RTG): Using DRS 500 wheels, with a load capacity of over 100 tons, to ensure continuous operation under high-frequency take-off and landing.

● Automated warehouse shuttle: Using the DRS 112 model, a precise walking track, suitable for the high-density storage system.

● Rail transfer platform vehicle (RGV): Equipped with DRS 315 wheels, it can achieve low-noise operation under high load.

● Clean room handling equipment: Combined with non-standard DRS aluminum wheels or polyurethane-coated wheels, it meets dust-free operation requirements.

Demag DRS intelligent drive system is becoming the core drive solution in the field of modern heavy-duty mobile equipment with its strong carrying capacity, modular design, and intelligent expansion capabilities. It not only improves the reliability and flexibility of equipment operation but also provides strong technical support for the realization of intelligent manufacturing and digital management.

If you need to obtain DRS series product specifications, 3D models, or integrated selection solutions, please contact us further. We can provide a complete drive solution based on your equipment conditions.

Demag DRS-M 160 wheel block: 7-ton load capacity for heavy-duty box stacker cranes, ideal for multi-layer stacking & thick-walled/semi-finished boxes, ensuring stable operation & low maintenance.

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.