Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In the evolving world of crane technology and industrial transport systems, the DRS wheel block travel unit has become a core component in delivering precise motion, handling heavy loads, and ensuring long-term durability. While standardized models meet many basic needs, tailor-made DRS solutions provide the adaptability and performance demanded by modern applications across various sectors—from shipyards and steel mills to automated warehouses and cleanroom logistics.

What is the DRS wheel block travel unit system?

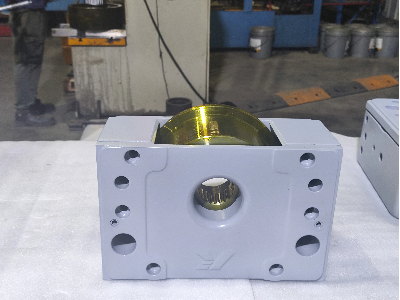

A standard drs travel unit consists of a travel wheel, housing, bearing set, and, when motorized, a gearbox and drive unit. These wheel blocks come in various diameters and configurations, typically ranging from drs 112 to drs 500 models, suitable for loads up to 40 tons per wheel.

Configurations include:

Driven vs. Non-driven wheels

Single, double, or flangeless wheels

Mounting types such as pin connection, side mount, top plate, or end connection

The flexibility of the system makes it a perfect platform for customization and modular upgrades.

Why choose tailor-made solutions?

Off-the-shelf systems often fail to meet the nuanced demands of non-standard installations. Complex layouts, space limitations, high-temperature zones, or extreme loading cycles require engineered DRS travel units.

Key benefits of customization include:

Precise load matching to avoid over- or under-dimensioning

Optimized installation layout based on beam dimensions and wheel spacing

Enhanced durability with materials and coatings selected for local environmental challenges

Reduced lifecycle costs through longer wear life and simplified maintenance

Customization options offered

Shiyang offers a wide range of custom DRS wheel block configurations, including:

Wheel specifications:

Diameters from 112mm to 500mm

Tread widths to match specific rail profiles

Double flange, single flange, or flangeless with lateral guide rollers

Mounting methods:

Pin, top plate, end, and side connections to suit various crane beam designs

Drive configurations:

Integration with sew gear motors, torque arms, and offset gearbox mounting (e.g., a20 interface)

Materials and coatings:

Ggg70 ductile iron, forged 40ro high manganese steel for abrasion resistance

Polyurethane-covered wheels for low-noise, traceless operation

Corrosion-resistant coatings for offshore or humid environments

Optional features:

Anti-derailment devices

Guide rollers

High/low temperature tolerance

Custom machining for mounting fit

Applications across industries

Tailor-made DRS systems are widely adopted in:

Overhead and gantry cranes in steel fabrication and shipbuilding

Rail-guided transfer carts in factory automation systems

Warehousing and logistics, especially for AGV or RGV systems requiring quiet and traceless motion

Cleanroom environments, using polyurethane wheels to minimize particulate generation and vibration

Case studies/project examples

Example 1: Compact crane end beam system

A customer in Southeast Asia required DRS units that fit a compact beam with limited height. Shiyang redesigned the mounting bracket and flange profile, reducing system height by 30% while maintaining full load capacity.

Example 2: High-load steel mill application

Heavy-load drs 500 blocks were custom-manufactured using 40ro forged steel for a steel rolling plant, with a reinforced housing and additional thermal-resistant seals.

Example 3: Low-noise warehousing AGV wheels

Drs 160 polyurethane-covered wheels were deployed for an automated warehousing system to reduce operational noise and prevent floor scarring.

Shiyang’s custom manufacturing capabilities

As a trusted DRS wheel block manufacturer, Shiyang provides complete in-house services:

Design & engineering: Custom drawings, load simulation, and 3D modeling

Production facilities: Full casting, CNC machining, polyurethane casting, and assembly

Flexible moq and fast prototyping: Ideal for both small-batch trials and large-scale projects

Installation & technical support: On-site guidance, product matching, and global shipping

Custom DRS wheel blocks offer unmatched flexibility, performance, and reliability across demanding industrial environments. Whether you're building a new crane system, upgrading a transfer cart, or addressing site-specific challenges, tailor-made DRS solutions are key to maximizing equipment life and operational efficiency.

Contact Shiyang today to explore a custom-engineered wheel block solution for your project needs—delivering quality, precision, and support from design to deployment.

Demag DRS-M 160 wheel block: 7-ton load capacity for heavy-duty box stacker cranes, ideal for multi-layer stacking & thick-walled/semi-finished boxes, ensuring stable operation & low maintenance.

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.