Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In the stereo garage, a rail-guided shuttle (RGV trolley) is the core equipment to realize efficient horizontal transportation of vehicles, and the Demag wheel block system, as its core driving component, with high load capacity, precise positioning and low maintenance characteristics, has become the key to improving system stability and efficiency. The following is an analysis from two aspects: common models and structural characteristics.

Common types and applicable scenarios

Demag wheel group provides multiple series of modular solutions for different load requirements of RGV trolleys:

• DRS-M series (lightweight)

Model range: DRS-M 112 to 200, covering loads of 2.75 tons to 10 tons.

Application scenario: RGV trolleys are suitable for small and medium-sized stereo garages to meet the needs of frequent start-stop and lightweight transportation. For example, the DRS-M 200 model is often used for shuttles with a single load of no more than 10 tons, suitable for private residences or commercial complex garages.

• DRS Series (Heavy Duty)

Model range: DRS 250 to 500, with load capacities ranging from 16 to 40 tons, and some customized models even support overweight loads of 60 tons.

Application scenarios: used in large public multi-story garages or industrial parking systems. For example, the DRS 500 model can drive RGV trolleys carrying multiple large SUVs to ensure the stability of heavy vehicle transportation.

Structural features and technical advantages

Demag's travel wheel set significantly improves the operating performance of the RGV trolley through optimized design and material technology:

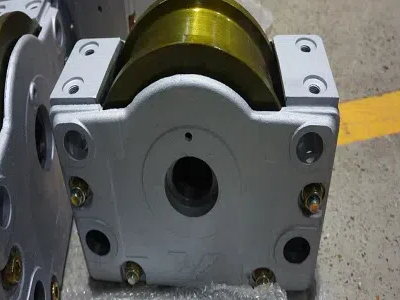

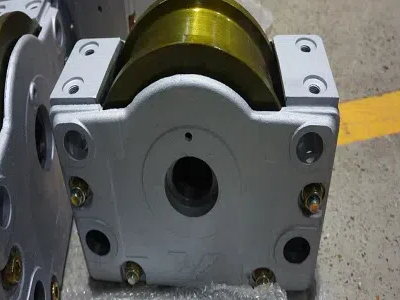

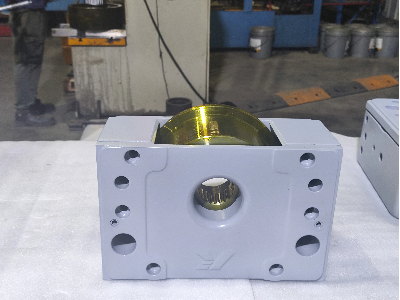

• Modular and highly compatible design

Flexible adaptation: The wheel box adopts a modular structure and supports top, pin, or end connection, which is convenient for rapid integration with customer-customized frames.

Compact layout: The lightweight shell design (such as the DRS-M series) reduces the occupied space and adapts to the narrow track environment of the multi-story garage, while maintaining a high ground clearance to avoid ground obstacles.

• Wear-resistant materials and strengthening technology

Wheel material: Forged with ductile iron, stainless steel, the tread hardness reaches HRC40-48 after quenching, and the depth of the hardened layer exceeds 10mm, which significantly improves the wear and fatigue resistance. Polyurethane coated wheels are suitable for epoxy floors and silent scenes.

Rim optimization: Some models (such as DRS 250 and above) adopt a rimless design with lateral guide wheels to reduce track friction; heavy-duty wheel sets meet the EN1563 GJS 700-2 standard through the rim to reduce slideway wear.

• Enhanced guidance and stability

Anti-derailment design: Equipped with lateral guide wheels and special brackets, even if the wheel set accidentally loosens, the bracket can still support the car body to run along the track to avoid derailment accidents.

Accurate positioning: Integrated laser alignment system to ensure synchronous operation of multiple wheel sets, positioning accuracy error is less than ±1mm, reducing additional losses caused by track deviation.

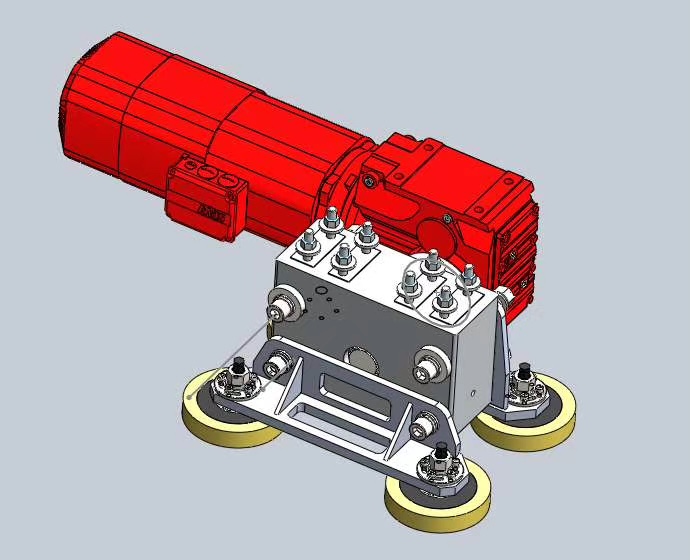

• Intelligent maintenance and drive system

Convenient maintenance: built-in mechanical wear indicator, intuitively displaying the wear status through color code changes; supports quick replacement design, wheel set replacement can be completed without disassembling the track, and maintenance efficiency is improved by 50%.

Variable frequency drive control: The combination of a variable frequency AC motor and reducer is adopted to achieve stepless speed regulation and low swing load movement, which is especially suitable for RGV operation scenarios that require frequent acceleration and deceleration.

Through model classification and structural innovation, Demag travel wheel set provides a full-scenario solution from light to super heavy load for the RGV trolley in the stereo garage. As the intelligent parking system develops towards high density and high automation, Demag's continuous breakthroughs in material technology (such as polyurethane optimization) and intelligent monitoring (such as digital twin integration) will further consolidate its technological leadership in the industry.

Demag DRS-M 160 wheel block: 7-ton load capacity for heavy-duty box stacker cranes, ideal for multi-layer stacking & thick-walled/semi-finished boxes, ensuring stable operation & low maintenance.

The Demag driven wheel block system is a high-performance, modular wheel unit widely used in cranes, transport systems, machine tool gantries, transfer carts, and heavy-duty handling applications.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.