Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

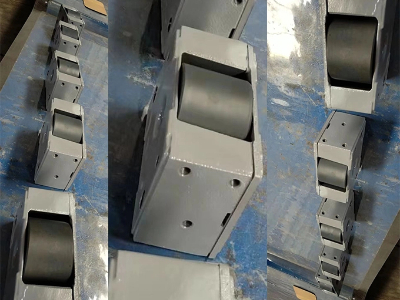

In automated material handling systems, flangeless DRS wheel blocks made from polyamide are increasingly becoming a popular choice, especially in applications like Rail-Guided Vehicles (RGVs), conveyor systems, and compact track-based machinery. But what makes polyamide wheel blocks so suitable for these roles?

What is polyamide?

Polyamide, commonly referred to as nylon, is a high-performance engineering plastic known for its excellent mechanical strength, wear resistance, and self-lubricating properties. When used in wheel applications, polyamide offers several key advantages over traditional materials:

• Lightweight yet strong: Ideal for high-speed operations and lightweight equipment where reducing overall system mass is critical.

• Excellent wear resistance: Ensures long service life even under continuous rolling and sliding friction.

• Low friction coefficient: Reduces energy consumption and heat buildup, supporting longer run times.

• Good chemical and oil resistance: Can operate in harsh industrial environments.

• Shock absorption: Provides moderate vibration damping without compromising structural integrity.

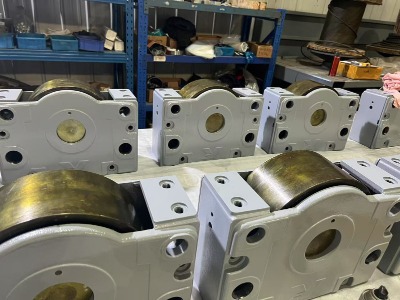

Structural highlight: Double-sided bearings

A notable feature of modern flangeless polyamide DRS wheel blocks is the double-sided bearing design, which improves stability, load distribution, and operational smoothness.

Dual bearing support reduces shaft deflection, making it ideal for precise motion control.

This configuration also extends bearing life and minimizes maintenance requirements.

Combined with the lightweight polyamide core, the assembly ensures a smooth ride with minimal friction.

Why use flangeless wheels?

Flangeless DRS wheels are typically used in applications where:

Lateral guidance is provided by the track rather than by wheel flanges.

Compact design is necessary, especially in systems with limited clearance.

Reduced rail and wheel wear is desired, as flangeless wheels cause less side contact stress.

Such wheels are perfect for modern automated systems where track accuracy is high and space-saving is a priority.

Applications in RGVs and industrial equipment

Polyamide flangeless DRS wheels are widely used in:

RGVs (Rail-Guided Vehicles) for warehousing and logistics automation

Assembly lines in the automotive and electronics industries

Cleanroom transport systems where metal contact and contamination must be minimized

Conveyor trolleys, shuttles, and telescopic arms

Their lightweight construction and resistance to wear make them ideal for repetitive tasks involving high speed and medium load.

If you’re seeking a lightweight, durable, and low-maintenance solution for your precision track systems, the flangeless polyamide DRS wheel block is a smart upgrade. From double-sided bearings to its self-lubricating properties, polyamide offers long-lasting performance in the most demanding automated environments.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.