Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

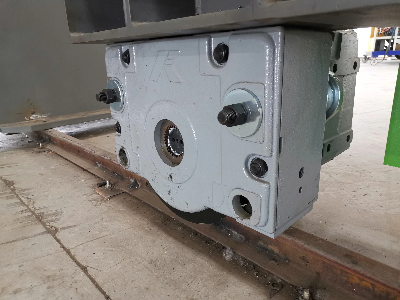

A harbor gantry crane is one of the most critical machines in modern ports, used to lift, transfer, and position heavy shipping containers or bulk cargo between vessels and the quay. Running on parallel rails along the dock, these cranes must operate with high precision, reliability, and endurance—often in harsh coastal conditions where salt, moisture, and abrasive dust are ever-present.

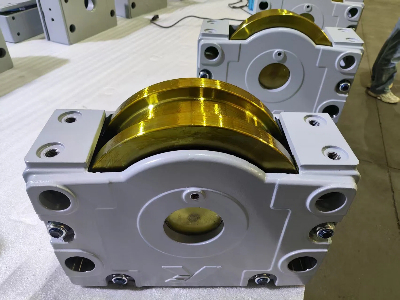

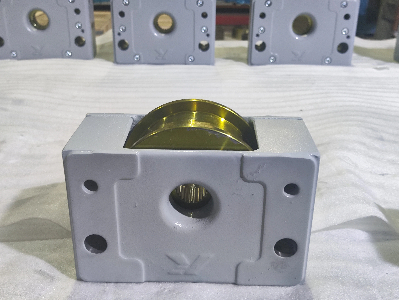

At the core of their mobility system is the travel wheel block. In the Demag DRS wheel block system, the wheel, housing, bearings, and sealing components form an integrated, factory-assembled unit. This ensures maximum load-bearing strength, precise movement, and long service life, even under continuous heavy-duty operation.

Function of the travel wheel block in harbor gantry cranes

Load transfer: Safely bears the crane’s total weight, including its maximum lifting load, and distributes it to the rails.

Smooth travel: Provides stable, low-vibration rolling for accurate positioning during loading and unloading.

Guidance & alignment: Keeps the crane tracking perfectly on the rails, even in high winds or when traversing curves.

Energy efficiency: Reduces rolling resistance, lowering drive motor strain and improving energy use.

Anti-slip: The wheel surface can be specially treated to prevent slipping. When working near water, the double-rim track wheels can reduce the risk of slipping.

Wheel material options for coastal applications

To meet the demands of marine environments, DRS crane wheels are available in a range of materials to balance strength, corrosion resistance, and cost-effectiveness:

Ductile iron: Offers excellent shock absorption and good wear resistance at a lower cost; suitable for general port operations.

Stainless steel: Highly corrosion-resistant, ideal for environments with constant salt spray and high humidity.

Forged steel: Delivers superior strength, impact resistance, and wear performance, making it the best choice for extremely heavy loads and high-frequency usage.

Coastal environment challenges and DRS advantages

Harbor gantry cranes operate in environments that accelerate wear and corrosion. Demag DRS wheel blocks are engineered with:

Marine-grade protective coatings to resist saltwater damage

Sealed precision bearings to block moisture and abrasive particles

Precision-machined tread surfaces for consistent rail contact and reduced wear

Modular, quick-replacement design to minimize downtime during servicing

Applications and replacement

The DRS crane wheel is used in new crane builds and as a direct replacement in maintenance or refurbishment projects. Thanks to its modular design, wheels can be swapped with minimal disassembly, keeping harbor operations running without costly delays.

With proven durability, adaptable materials, and a design optimized for the demanding conditions of coastal ports, Demag DRS rail wheels ensure harbor gantry cranes remain safe, efficient, and operational for years to come.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.