Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

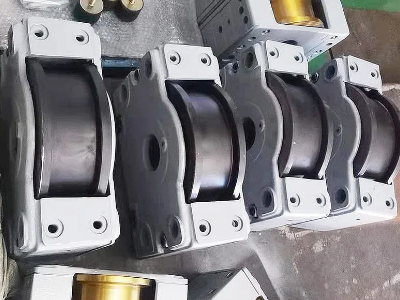

Demag double-flange track wheels include double-flange travel wheel blocks, V-type track wheels, and O-type travel wheels. With their high load capacity, impact resistance, and anti-derailment design. They have become the key configuration of heavy equipment in scenarios such as automated material handling, load-bearing lifting, and cargo transfer.

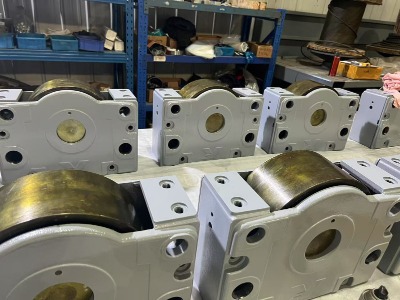

Material and Process Advantages

• Material selection: Ductile iron or carbon steel is used, with good load capacity (2.75 t- 40 t) and wear resistance.

• Process treatment: The hardness and wear resistance of the wheel are improved through the quenching forging process, extending the service life.

• Precision machining: The wheel axle hole tolerance is controlled at H7 level (±0.018mm) to ensure the accuracy of the bearing fit; the double-flange symmetry error is ≤0.1mm to avoid track wear caused by eccentric load.

• Customizable: It can be customized for special properties such as high and low temperature resistance, material, size, or process requirements.

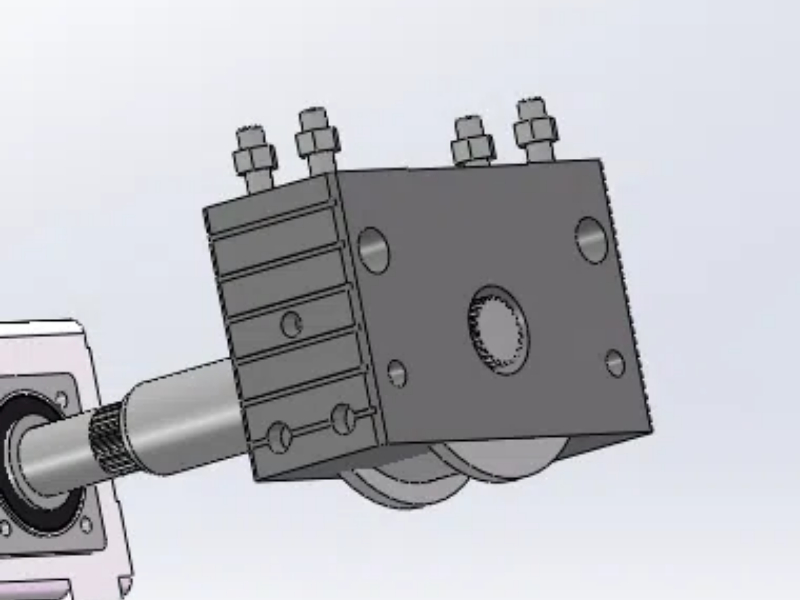

Diverse Connection Methods

To adapt to the installation requirements of different equipment, Demag track wheels provide a variety of connection methods:

• Side connection: suitable for equipment with limited space or requiring lateral installation.

• Pin connection: fixed by a pin shaft, easy to install, suitable for occasions that require quick replacement.

• Top connection: installed from the top of the equipment, suitable for equipment with specific structures.

• End connection: connected from the end of the wheel, suitable for specific installation requirements.

Advantages of Double Flange Design

The double flange structure has the following advantages in track wheel design:

• Improved guidance: The double flange design enhances the guiding ability of the wheel on the track and prevents derailment.

• Enhanced stability: The double flange structure provides better stability when running under high load and high speed.

• Reduce wear: The double flange can disperse the load, reduce the contact stress between the flange and the track, and extend the service life.

Typical Application Scenarios

Demag double flange track wheels are widely used in the following industrial fields:

• Lifting equipment, such as bridge cranes, gantry cranes, etc., requires high load and stable operation.

• Automated warehousing systems, such as stackers and shuttles, require high positioning accuracy and reliability.

• Heavy handling equipment, such as industrial transport vehicles, rail transport vehicles, etc., requires wear resistance and long life.

• Special working condition equipment, such as equipment in high temperature, low temperature, high humidity, or corrosive environments, requires special resistance of materials and processes.

Whether it is a 2.75t light conveyor line or a 40t heavy crane, Demag double-flange track wheels have become an ideal choice for industrial equipment travel systems with their high load capacity, excellent wear resistance, diverse connection methods, and double-flange design advantages. For more product information or customized solutions, please contact our professional team. We will provide you with a full range of technical support and services.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.