Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

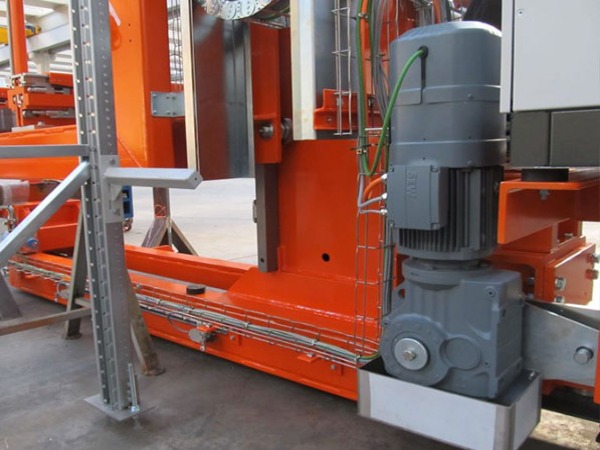

Stacker cranes are the backbone of high-bay warehouses and automated storage/retrieval systems. While controls, drives and sensors coordinate each move, the wheel block (drive unit) that converts torque into reliable linear motion is a mission‑critical subsystem. The DRS wheel block system is designed to deliver compact, serviceable, and accurate traction for these heavy-duty, high-duty-cycle machines. Selecting the right drive unit directly affects uptime, positioning accuracy, and lifecycle costs.

Key Functional Roles in Stacker Cranes

1. Provide traction and transmit drive torque to the rails for longitudinal travel.

2. Support static and dynamic loads from the crane and payload.

3. Ensure precise position control via feedback devices (encoders or resolvers) and low backlash gearing.

4. Offer fail-safe braking and emergency stop performance for personnel and goods protection.

5. A reliable DRS drive unit is essential for safe, repeatable, and high-throughput operation.

Typical Design Features and Benefits

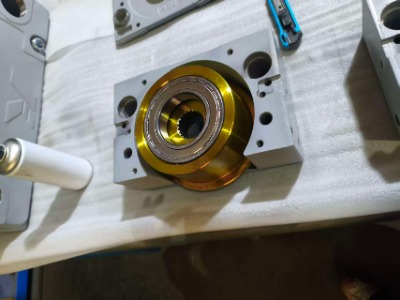

1. Integrated motor-gear-brake module: reduces assembly complexity and keeps the drivetrain compact. Integration minimizes alignment errors and reduces the number of rotating interfaces that require maintenance.

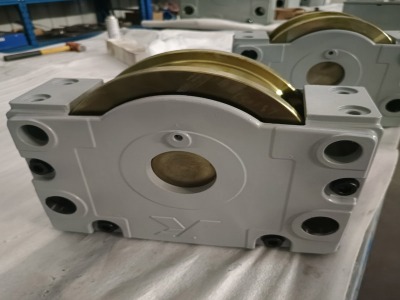

2. Compact modular design: Facilitates retrofit and replacement—service technicians can swap a single drive block rather than disassemble multiple components.

3. Wheel options and floor friendliness: Drive units are commonly offered with durable wheel treads; vulcanized polyurethane-coated wheels are often recommended because they balance traction, abrasion resistance, and floor protection on painted or epoxy surfaces.

4. Sealed bearings and protective housings: improve contamination resistance in dusty warehouse environments and extend bearing life.

5. Built-in feedback and diagnostics: Encoder or resolver feedback enables precise positioning and coordinated motion; many modern drive units support condition monitoring for vibration, temperature, and electrical load—useful for predictive maintenance.

6. Service access and replaceability: Bolted flange interfaces and standardized mounting reduce crane downtime during unit exchange.

Why DRS Drive Units Matter for Stacker Cranes

1. Improved positioning accuracy: Integrated low-backlash gearing and direct feedback reduce cumulative errors, improving pick/place precision in dense pallet grids.

2. Higher uptime and easier maintenance: Modular replacement and fewer individual components lower mean time to repair (MTTR).

3. Lower lifecycle cost (TCO): Although a fully integrated drive unit can carry a higher initial cost than basic component assemblies, the reduction in installation time, maintenance frequency, and unplanned downtime often yields lower TCO.

4. Safer emergency response: Industrial-grade brakes and controlled deceleration behaviors enhance personnel and inventory safety during fault conditions.

Conclusion

The Demag DRS wheel block system—also referred to as the drive unit—provides a compact, serviceable, and precise propulsion solution for stacker cranes. By consolidating motor, gearbox, brake, wheel, and feedback into a single module, these drive units reduce downtime, improve positioning, and lower lifecycle costs when specified and maintained correctly. For facilities aiming to maximize uptime in high-throughput automated warehouses, investing in modular, proven drive units pays off through higher reliability and easier maintenance.

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.