Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

The Wheel Block System is a cornerstone subsystem in crane engineering, playing a vital role in the structural integrity of overhead, gantry, and tower cranes. Beyond mere displacement, its core value lies in ensuring structural stability and precise load distribution during high-capacity lifting operations.

Core Components and Engineering Architecture

A professional-grade wheel block system is a precision-integrated assembly, primarily comprising:

High-Load Wheels: Typically featuring polyurethane treads for noise reduction and floor protection, or hardened steel for heavy-duty industrial rails.

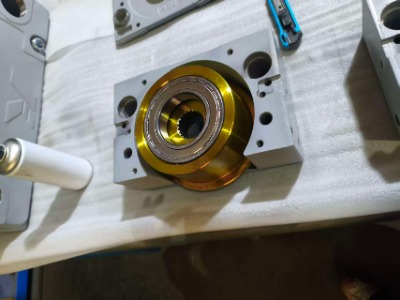

Precision Axles and Bearings: Engineered specifically to withstand intense radial and axial loads.

Modular Bearing Housings: Precision-engineered to facilitate ease of maintenance and ensure optimal alignment accuracy.

Key Performance Indicators

1. Operational Safety and Load DistributionIn the lifting industry, safety is the absolute priority. Precision-manufactured wheel blocks ensure weight is distributed uniformly across the crane rails. By minimizing mechanical fatigue and mitigating derailment risks, these systems protect both operators and the structural integrity of the facility.

2. Superior Operational EfficiencyModern wheel block designs prioritize ultra-low rolling resistance. This efficiency enables smooth start-stop transitions and effectively eliminates "rail gnawing" (misalignment wear), thereby shortening duty cycles. In high-throughput industrial environments, this translates directly into enhanced project productivity.

3. Application Flexibility and Environmental AdaptabilityWhether in cleanroom environments requiring non-marking polyurethane treads or harsh outdoor construction sites, wheel block designs must be highly adaptable. Customized tread designs allow cranes to operate across diverse terrains and rail types without sacrificing traction or stability.

4. Structural Durability and Wear ResistanceCrane wheels are subject to immense compressive stress. By utilizing premium materials and advanced heat treatment processes, high-quality wheel blocks resist deformation and flange wear. This durability ensures the crane maintains its rated load capacity throughout thousands of operational hours.

Customized Solutions

The performance of a crane is only as reliable as its travel system. Contact our engineering team today for bespoke crane component solutions tailored to your specific requirements.

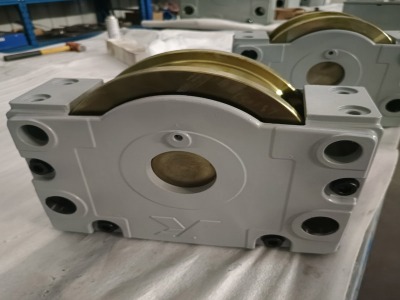

The wheel blocks is the most critical load-bearing and execution component for crane drive systems, whose performance directly impacts the efficiency and safety of the entire material handling system.

The Demag DRS400-A90-B rail sweeping device ensures clean tracks and smooth, reliable performance for heavy-duty DRS wheel block systems.

The DRS 315-NA-A-90-B-X-X is a heavy-duty non-driven wheel block unit featuring a spheroidal graphite cast iron dual-flange design and pin connection.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.