Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

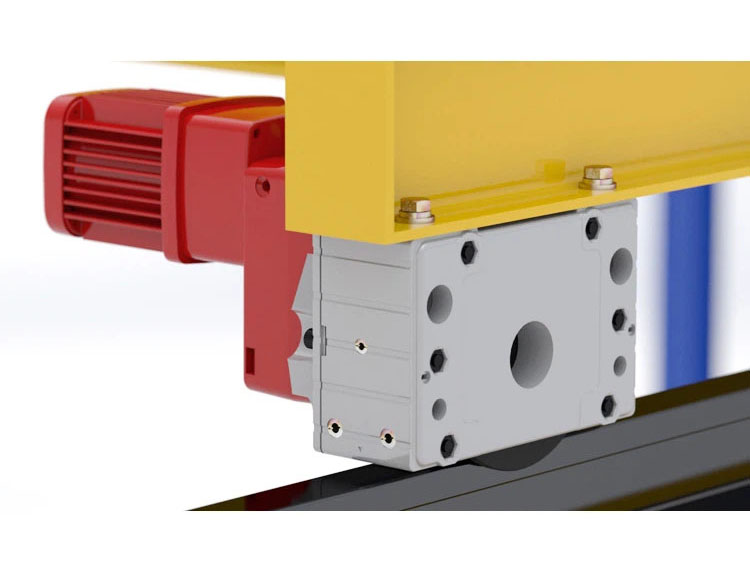

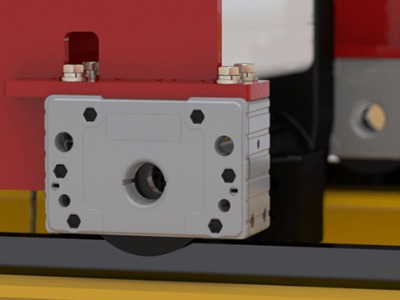

In industrial applications, equipment reliability directly determines production line continuity and operational costs. For crane traveling systems, the wheel set is the most critical load-bearing and execution component, whose performance directly impacts the efficiency and safety of the entire material handling system. The DRS 160 wheel set, with its outstanding technical features and specialized design for extreme operating conditions, has become the preferred solution in high-demand industries such as steel, ports, and heavy machinery.

Solving Application-Specific Challenges: How the DRS 160 Handles Three Extreme Operating Conditions

High Load & Heavy Impact – Steel Plants & Heavy Assembly Shops

In steel plant slab yards, cranes frequently transport hundreds of tons of hot slabs. In heavy assembly workshops, the lifting of large structural components generates significant impact loads. Conventional wheel sets are prone to tread spalling, flange cracking, and even bearing fractures under such conditions. The DRS 160, however, delivers near-perfect performance:

High Load Capacity & Fatigue Resistance: Made from high-strength ductile cast iron (GGG-70) with deep quenching treatment, the tread achieves a hardness of HRC55 or higher, while the core retains toughness, extending fatigue life by over three times.

Impact-Resistant Structure: Tapered roller bearings are designed to withstand extremely high radial and axial loads, preventing damage caused by eccentric loading or impact.

Dusty, High-Temperature & Corrosive Environments – Coal Washing Plants, Foundries & Coastal Ports

Coal dust in washing plants, metallic dust in foundries, and salt-laden humidity in coastal ports can accelerate seal failure, bearing wear, and metal corrosion. The DRS 160 addresses these challenges with:

Enhanced Corrosion Resistance: All external surfaces receive special anti-rust treatment (e.g., galvanizing or epoxy anti-corrosion coating), effectively resisting acidic/alkaline gases and salt spray corrosion.

High Precision & Low Noise Requirements – Automated Warehouses & Precision Manufacturing Facilities

In AS/RS automated storage systems, cranes must operate smoothly, quietly, and with high positioning accuracy. Any vibration or noise can degrade overall system performance. The DRS 160 delivers:

High-Precision Manufacturing & Balancing: Each wheel set undergoes dynamic balancing (Grade G6.3) before delivery, ensuring smooth operation and significantly reduced vibration.

Optional Low-Noise Polyurethane-Coated Wheels: For noise-sensitive environments, polyurethane-coated wheels are available, reducing operational noise by over 15 dB(A) while protecting rail surfaces.

How to Select the Right Wheel Set for Your Application?

Choosing the DRS 160 is not just selecting a product—it's adopting a complete solution. We recommend evaluating your needs based on the following dimensions:

1. Load Analysis: Maximum wheel load, impact factor, and potential eccentric loading.

2. Environmental Assessment: Temperature, humidity, dust concentration, and presence of corrosive substances.

3. Precision & Noise Requirements: Need for low vibration, low noise, or high positioning accuracy.

4. Maintenance Cost Objectives: Focus on reducing total cost of ownership (TCO) or minimizing downtime.

The DRS 160 wheel set, built on a foundation of technical reliability and precisely engineered for specific operating conditions, is proving its value across heavy industrial applications worldwide. Whether facing extreme loads, harsh environments, or high-precision demands, the DRS 160 provides robust, stable, and dependable mobility support for your equipment.

For more information, please contact us.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.