Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Crane wheel blocks are the critical interface between heavy equipment and its operational tracks, enabling the seamless movement of massive loads across sectors ranging from manufacturing and logistics to construction and port operations.

Core Specifications: Tailored to Industrial Demands

Crane wheel blocks are defined by their adaptability to diverse operational requirements, starting with their foundational specifications:

1. Size Range

Available in diameters from Φ112 mm to Φ500 mm, these wheel blocks cater to applications spanning light-duty material handling to heavy-duty port cranes and gantry systems. The size directly correlates with load capacity, with larger diameters supporting higher weights and smoother rolling at scale.

2. Premium Wheel Material

Constructed from GGG70 ductile cast iron, a high-strength, wear-resistant alloy, which crane wheel blocks deliver exceptional load-bearing and compressive capabilities. Ductile iron outperforms traditional gray iron here, offering enhanced toughness to withstand shock loads and dynamic stress, while specialized surface treatments further boost wear resistance for prolonged service life.

3. Wheel Types for Targeted Performance

The design of the wheel’s flange and tread dictates its suitability for specific tracks and operational needs:

Double Flange: Flanges on both sides provide lateral stability, ideal for standard overhead crane tracks and low-speed, heavy-load scenarios.

Single Flange: A single-side flange suits ground-based tracks, where alignment is guided by the track’s edge.

Flangeless: Designed for flat surfaces or linear drive systems with external guiding mechanisms, these wheels prioritize flexibility.

Grooved Flange: V-shaped or concave treads ensure precise directional control, critical for automated systems like aisle stacker cranes that require millimeter-level accuracy.

Polyurethane-Coated: A polyurethane tread layer reduces noise, dampens vibration, and protects delicate surfaces, making them perfect for indoor, low-noise environments.

4. Versatile Mounting Solutions

To integrate with diverse equipment designs, crane wheel blocks offer four primary mounting options:

Top Mounting: Bolted to the top of end carriages.

Pin Mounting: Secured via a central pin for pivotable movement.

Single-Side Mounting: Attached to one side of the frame, ideal for compact or asymmetrical equipment.

End Mounting: Fixed to the end of beams, typical in gantry cranes and mobile platforms.

5.Customization Capabilities

For unique or non-standard applications, manufacturers offer bespoke production based on client-provided drawings. This flexibility ensures compatibility with legacy equipment, specialized tracks, or project-specific load requirements—eliminating the limitations of off-the-shelf components.

Whether you’re designing a new gantry crane, upgrading a logistics system, or maintaining legacy equipment, choosing the right crane wheel block isn’t just a purchase—it’s an investment in reliability, safety, and long-term operational success. Contact us!

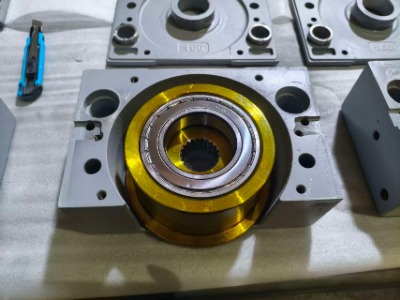

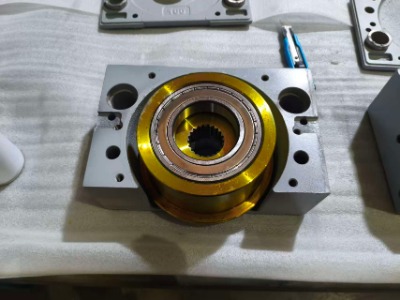

DRS-160-A45-B-0-18B-H-A30 highlights key technical features such as the spheroidal graphite cast iron material, double-flanged wheel design, and modular mounting interfaces.

DRS 112-MA30-A-47-K-H-A10 wheel block features modular design, MA30 spline shaft, and A10 gearbox compatibility optimizing industrial mobility in automated warehousing and automotive production lines.

Demag wheel blocks for cleanroom cranes have some special requirements in design and application, mainly to ensure efficient and safe operation in highly controlled environments such as cleanrooms.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.