Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

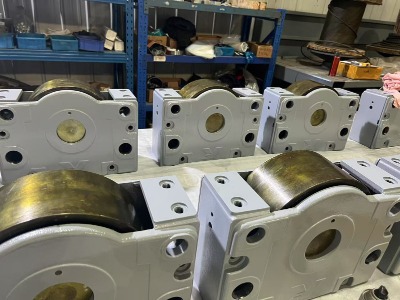

The DRS-112-MA30-A-60-B-H-X 2.75-ton wheel module system is a high-performance solution specifically engineered for material handling, automation, and heavy industrial machinery. Integrating advanced drive technology, flanged wheels, and stringent tolerance standards, this system delivers exceptional durability and operational precision, ensuring stable performance even in the most demanding industrial environments.

Core Features and Technical Highlights

At the heart of the system is a driven wheel module designed to provide smooth and consistent motion for applications such as conveyor systems, bridge cranes, and automated guided vehicles (AGVs).

Axle Specification: 30 mm diameter axle, optimized for high load capacity and alignment stability

Advantages: Significantly reduces wear, extends service life, and maintains high-precision operation under heavy loads

High-Strength GJS Flanged Running Wheel

The running wheel is manufactured from ductile cast iron (GJS/GGG), offering excellent toughness and impact resistance.

Double Flange Design: Effectively prevents derailment and ensures stable travel along the rail

Type A Tread (b1): Reduces rolling resistance, adapts to various rail geometries, and enhances application efficiency

Robust Pin Connection and Horizontal Guide Rollers

Pin Connection: Simplifies installation and maintenance while maintaining structural strength

Guide Roller Assembly: Provides lateral stability and precise guidance, meeting industry standards and minimizing downtime during system integration

Grade 2 Precision Manufacturing

The DRS-112 series strictly adheres to VDI 3576 Grade 2 tolerance standards, ensuring dimensional accuracy and part interchangeability.

Advantages: Minimizes operational deviation, guarantees repeatable positioning accuracy, making it ideal for robotics, CNC equipment, and automated systems

Flexible and Customizable Configuration

This wheel module system supports configuration adjustments in 1 mm increments, allowing engineers to tailor solutions based on load and spatial requirements.

Direct Drive Design: Eliminates the need for gearboxes, reducing system complexity and maintenance costs while ensuring efficient power transmission

Typical Application Scenarios

The DRS-112-MA30-A-60-B-H-X wheel module excels in industrial fields requiring high durability, precision, and adaptability, including:

1. Automotive assembly lines

2. Warehousing and logistics systems

3. Steel processing and heavy manufacturing

4. Foundries and outdoor installations in harsh environments

Conclusion

The Demag DRS-112-MA30-A-60-B-H-X wheel module system integrates innovative technology, precision engineering, and outstanding reliability to effectively meet the challenges of modern industrial motion control. With its GJS flanged wheels, precision axle design, tight-tolerance manufacturing, and highly customizable configuration, it offers engineers a cost-effective and dependable solution.

Shiyang provides the complete Demag DRS wheel module series, delivering reliable motion solutions that enhance equipment performance and operational efficiency in the most challenging industrial environments.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.