In recent years, the rapid advancement of industrialization in Vietnam has generated strong demand for high-performance material handling equipment, particularly in key sectors such as automotive parts manufacturing, electronics assembly, and logistics warehousing. A leading automotive parts manufacturer in Vietnam specializes in supplying precision components to global automotive brands.

To meet growing capacity demands and strict quality control requirements, the company purchased a batch of Demag overhead cranes for its new factory in the northern industrial zone.However, during the operational stage, the original wheel assemblies of the cranes began to suffer frequent wear issues. This led to increased downtime for equipment maintenance and rising operating costs, which not only affected production line continuity but also posed potential safety hazards.

The factory operates on a 24-hour non-stop schedule, requiring the cranes to repeatedly lift heavy loads. Furthermore, the high-temperature, dusty environment within the workshop accelerated the wear on the wheel assemblies. To address this issue, Demag recommended replacing the original components with the DRS 250 Wheel Block System, leveraging its proven reliability and adaptability to harsh operating conditions.

The Challenges

1. High-Intensity Operational Load

The cranes operate continuously for 24 hours with frequent start-stop cycles and heavy lifting, requiring wheel blocks with excellent wear resistance and load-bearing capacity.

2. Harsh Working Environment

Summer temperatures in the workshop reach up to 38°C, combined with floating metal dust. This environment easily leads to bearing corrosion and jamming (seizure).

3. Cost Control Requirements

The company sought to reduce maintenance costs while ensuring crane performance and safety, necessitating a replacement solution with a high cost-performance ratio.

4. Compatibility with Demag Cranes

The replacement wheel system had to perfectly match the mechanical structure and operating parameters of the existing Demag cranes to ensure seamless integration and stable operation.

The Solution: DRS 250 Wheel Block System

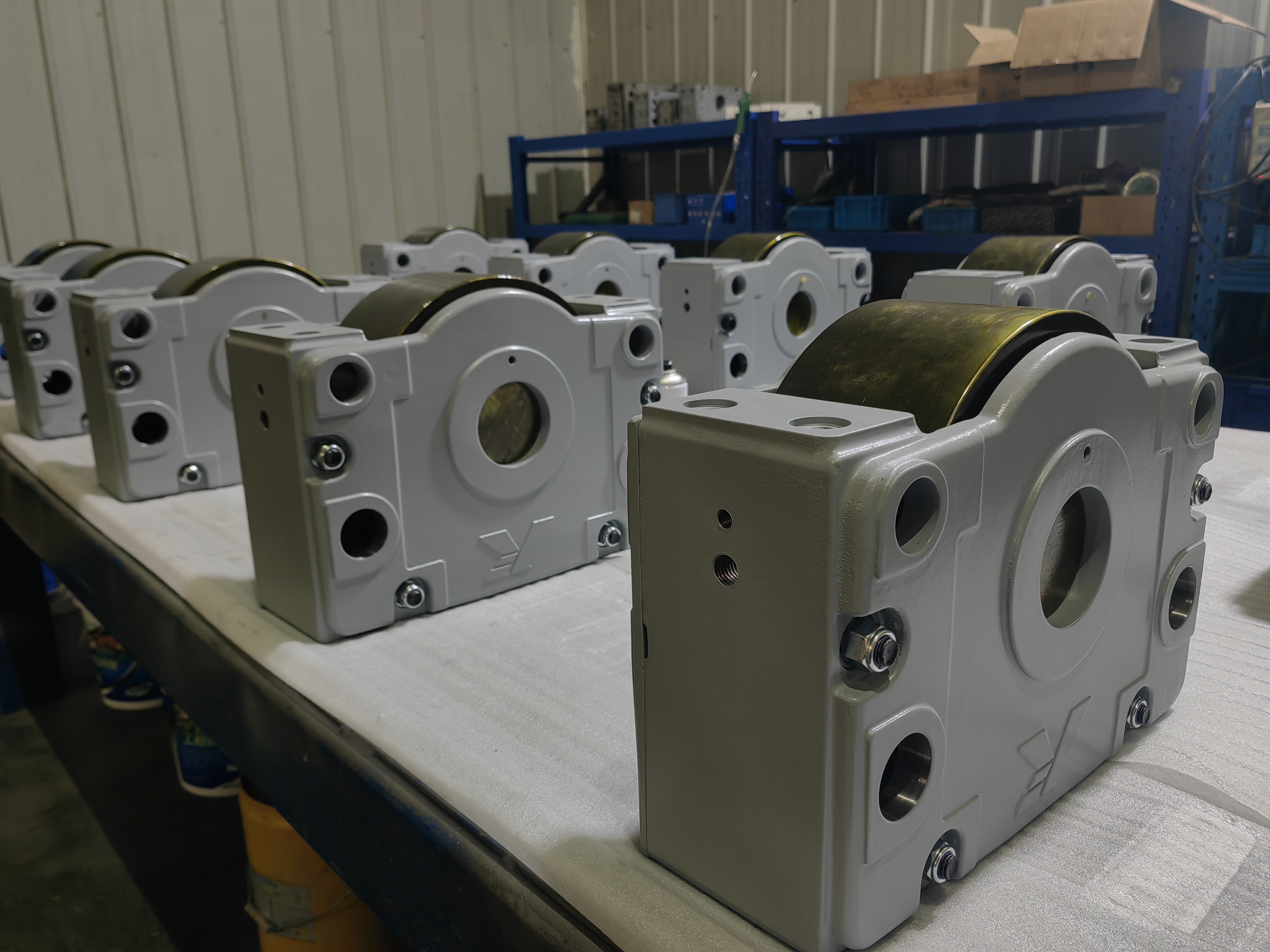

After a thorough evaluation, the company decided to adopt the DRS 250 wheel block system for all 8 Demag overhead cranes in the factory. The system’s core advantages in addressing the specific challenges are as follows:

1. High-Quality Structural Design

The DRS 250 features a single-piece cast steel housing with high structural strength and impact resistance, effectively withstanding the stresses generated by frequent heavy-load operations. The wheel body is made of high-strength alloy steel that has undergone surface tempering, significantly improving wear resistance and extending service life.

2. Advanced Bearing and Sealing Technology

Equipped with high-precision, high-load-capacity deep groove ball bearings, the system utilizes a multi-layer sealing structure (including oil seals and dust covers). This effectively blocks metal dust and hot air from entering the bearing interior, preventing corrosion and jamming, thus ensuring stable operation in high-temperature and dusty environments.

3. Perfect Compatibility with Demag Cranes

The DRS 250 wheel block system is tailored to the technical parameters of Demag cranes. Its dimensions and mounting holes precisely match the crane's trolley and rail systems. The installation process is simple and efficient, requiring no major modifications to the crane body. This ensures rapid commissioning and minimizes the impact on production.

4. Cost-Effective Operation

Compared to the original wheel components and other high-end alternatives, the DRS 250 system offers a more competitive price point while maintaining high quality. Furthermore, its superior wear resistance and low failure rate reduce the frequency of maintenance and replacements, significantly lowering the company's long-term operational and maintenance costs.

Conclusion

The successful application of the DRS 250 wheel block system on Demag cranes at this Vietnamese factory fully demonstrates its core advantages of high quality and cost-effectiveness. By precisely matching the operational needs of Demag cranes and adapting to the harsh working conditions of Vietnamese industrial workshops, the DRS 250 system has provided a reliable and economical solution for upgrading local material handling equipment. This case sets a benchmark for the application of the DRS series wheel block systems in the Southeast Asian industrial market and lays a solid foundation for future regional expansion.