Head Office

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

In lifting equipment and industrial automation systems, the wheel block system with gearbox is an important component that integrates drive, transmission and travel functions. The precise gear transmission mechanism converts the high-speed rotation of the motor into the low-speed and high-torque output required by the equipment, ensuring the smooth movement and precise positioning of heavy loads.

Gearbox features

• Realize power transmission and drive control

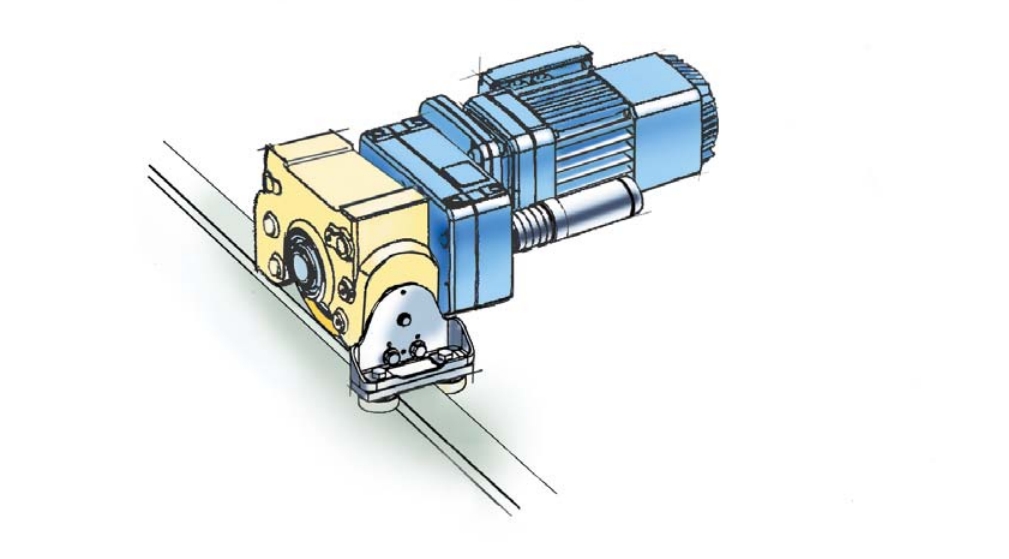

The travel wheel box with gearbox converts the high-speed output of the motor into a stable low-speed and high-torque output through the built-in reduction gear set, so that the equipment can move smoothly and efficiently along the track. This design is particularly critical for equipment that requires precise positioning and heavy-load operation.

• Integrated design, saving space

Components such as gearboxes, wheel sets, bearings and sealing systems are highly integrated in a compact structure, which is more convenient to install and more efficient to maintain, and is suitable for industrial scenarios with limited space.

•Adapt to various working conditions and drive requirements

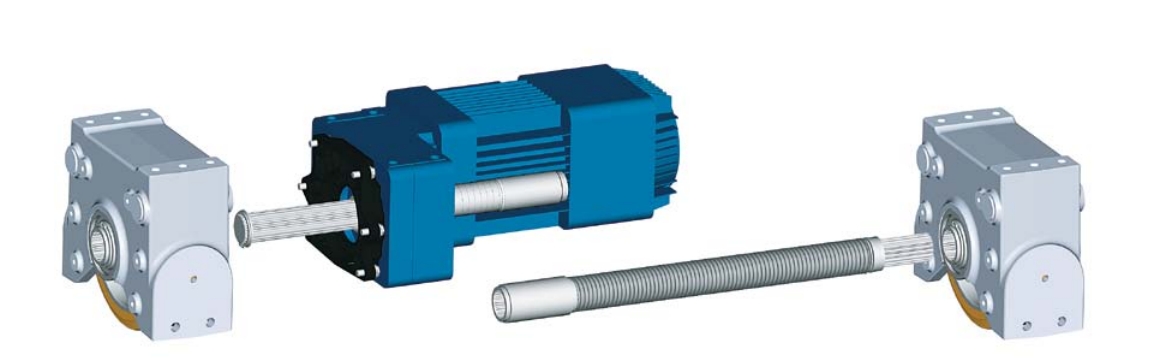

The gearbox can be matched with various drive motors, such as three-phase asynchronous motors, servo motors, etc., to meet various speed, torque and control requirements, and is an important drive component of modern intelligent manufacturing systems.

Maintenance recommendations for wheel block system with gearboxes

To ensure the long-term and efficient operation of Demag travel wheel boxes, users are advised to perform regular maintenance according to the following methods:

•Check and replace lubricating oil

The lubricating oil inside the gearbox plays a key protective role in gear meshing. It is recommended to check the oil level every 3-6 months and replace the gear oil regularly, especially under high temperature, high load or high frequency operating conditions. The replacement cycle should be shortened.

•Regularly tighten the connecting parts

Check whether the bolts between the wheel block and the main structure are loose to prevent displacement or connection failure due to vibration.

•Monitor the operating status

Listen to whether there is abnormal noise or vibration during the operation of the wheel block, and promptly discover and deal with hidden dangers such as gear wear and bearing failure.

•Do a good job of dust prevention and cleaning

The outer shell should be cleaned regularly, especially when working in dusty, oily or corrosive gas environments, and ensure good sealing to prevent impurities from invading the gearbox.

Precautions for purchasing a travel wheel block with a gearbox

Purchasing a high-quality wheel block system with a gearbox not only affects the performance and life of the equipment, but also affects the overall operational efficiency of the project. The following aspects deserve special attention:

•Confirm the load-bearing capacity

According to the actual load-bearing capacity, operating speed and frequency of use of the equipment, select the appropriate travel wheel block model and wheel diameter to ensure safe operation under the rated load. The general load-bearing capacity is between 2.75t and 40t.

•Reasonable selection of gear ratio

The gear ratio should match the performance of the selected motor to ensure that the output torque meets the operating requirements and the speed is controlled within the allowable range of the equipment.

•Adaptability and compatibility

The wheel block system should be well matched with key parameters such as track size, motor interface, and installation method. Customizable models should be selected when necessary.

•Pay attention to wheel material quality

The wheel material affects wear resistance and grip. For industries with high ground requirements (such as food and electronics), polyurethane-coated wheels can be selected; for heavy loads or high impact occasions, forged steel wheels or high-strength nylon wheels are recommended. Including wheels without rim, single rim, and double rim.

•Brand guarantee and after-sales service

It is recommended to choose Demag original or high-quality alternative manufacturers to ensure stable product quality, complete spare parts, and perfect technical support to reduce the difficulty of later operation and maintenance.

The Demag travel wheel block with gearbox has high integration and strong transmission efficiency. It is an indispensable key component for achieving efficient operation of equipment. Through reasonable selection, standardized use and regular maintenance, it can not only improve equipment performance, but also greatly reduce operating costs.

If you have special application requirements, please contact the professional technical team to obtain non-standard customized solutions and technical selection suggestions.

Contact Shiyang Industrial Machinery to get a tailored DRS wheel block system for cranes, transfer carts, and conveying system.

83-120/121, Wuzhou International Industry Expo, Xinwu District, Wuxi City, Jiangsu, China

sale10@kfqizhongji.com

Use the form below to get in touch with us.