PU-coated DRS wheel blocks for AGVs offer high load capacity, quiet operation, and wear resistance, ensuring smooth, safe, and durable performance in automated guided vehicle systems. The DRS system features various connection options, allowing for versatile installation and compatibility with existing equipment. This design enhances efficiency and ease of maintenance in demanding environments.

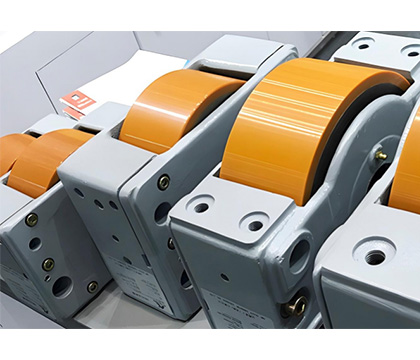

In order to suit various rails and ground, DRS wheel blocks have multiple shapes and designs – made of spheroidal-graphite cast iron (GGG 70), polyamide, or PU-coated DRS wheel blocks. Here we focus on polyurethane-coated wheels.

Features of PU-coated DRS wheel blocks

1. Each high-quality PU wheel has a high resilience performance.

2. These wheels are known for their excellent wear resistance and small compression deformation.

3. When working in low temperatures (as low as -40°C) or areas where the ground is frozen, the forklift truck can drive normally, thanks to these non-slip tires. Our polyurethane wheels for low-temperature environments have been patented.

Flangeless, concave polyurethane wheels for quiet operation that are kind to the runway. When DRS wheel blocks are coated with polyurethane, they are suitable for automated guided vehicles (AGVs) traveling, handling heavy loads up to 40 tons per wheel. These wheels are used on automated guided vehicles (AGVs). They bear the weight of the vehicle and the conveyed goods, transmit drive power from the motor to the track, and steer the vehicle.

With only a limited installation space available (in terms of diameter and width), AGV wheel blocks can withstand very heavy loads and ensure excellent grip on a range of different surfaces. They also have to be extremely wear-resistant, including in applications where tight cornering and on-the-spot rotation are essential. Low running resistance and low friction cornering are important for customers for reasons of energy efficiency, especially in view of the fact that AGVs are battery-operated.

Contact Shiyang Industrial Machinery to get a custom wheel block solution.